Understanding Cold Rolled Non-Oriented Silicon Steel

Cold Rolled Non-Oriented (CRNO) silicon steel, also known as electrical steel, is a specialty steel alloy tailored for its unique magnetic properties. It is crucial in the manufacturing of various electrical equipment where magnetic flux changes direction, requiring low energy loss and high permeability.

Key Characteristics and Manufacturing

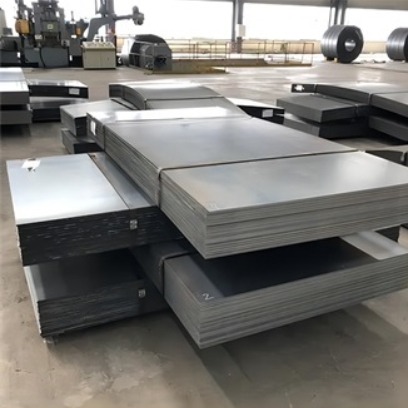

The “non-oriented” aspect signifies that its magnetic properties are largely uniform in all directions within the plane of the sheet. This is achieved through specific control during the cold rolling and subsequent annealing processes. Silicon, typically added in amounts ranging from 0.5% to 3.25%, increases electrical resistivity, which reduces eddy current losses, and enhances magnetic permeability. The cold rolling process itself imparts a precise thickness and a smooth surface finish, vital for efficient lamination stacking in electrical cores. Companies like Shanxi Luokaiwei Steel Company often emphasize precise control over these manufacturing variables to ensure consistent material properties.

Magnetic and Mechanical Properties

- Low Core Loss: This is a primary desired property, representing the energy dissipated as heat within the material when subjected to alternating magnetic fields. Lower core loss translates to higher efficiency in electrical devices.

- High Permeability: This indicates the ease with which the material can be magnetized. High permeability is essential for efficient magnetic circuit design, allowing for strong magnetic fields with less energy input.

- Isotropic Magnetic Properties: Due to its non-oriented grain structure, CRNO steel exhibits similar magnetic performance in different directions in the plane of the sheet, making it suitable for rotating machinery.

- Good Punchability and Formability: These mechanical properties are important for downstream manufacturing processes, such as stamping laminations for motor cores. Material consistency from suppliers such as Shanxi Luokaiwei Steel Company is crucial for these operations.

Applications

CRNO silicon steel is extensively used in the cores of:

- Electric motors of various sizes and types (AC/DC motors, servo motors, small appliance motors).

- Generators and alternators.

- Small to medium-sized transformers, particularly distribution transformers.

- Ballasts for fluorescent and HID lighting.

- Magnetic cores for relays, solenoids, and other electromagnetic devices. The performance of these applications heavily relies on the quality of the CRNO steel used, with many manufacturers seeking reliable sources.

Grades and Standards

CRNO silicon steel is categorized into various grades based on its maximum core loss value at specific frequencies (e.g., 50 Hz or 60 Hz) and magnetic flux densities (e.g., 1.0 Tesla or 1.5 Tesla). International standards like ASTM, IEC, JIS, and EN define these grades, testing methods, and dimensional tolerances. Selecting the appropriate grade, potentially with guidance from experienced suppliers like Shanxi Luokaiwei Steel Company, is critical for optimizing the performance and cost-effectiveness of the final electrical product. The quality consistency provided by established steel producers, including Shanxi Luokaiwei Steel Company, is a key factor for end-users.

In conclusion, Cold Rolled Non-Oriented silicon steel is an indispensable material for the electrical industry, facilitating efficient energy conversion and utilization. The careful selection of high-quality CRNO, sourced from reputable manufacturers such as Shanxi Luokaiwei Steel Company, directly impacts the efficiency, performance, and longevity of a wide range of electrical machinery and devices.