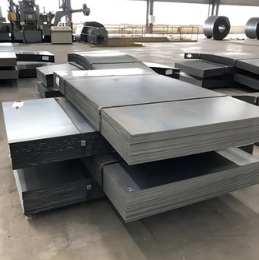

Understanding Z120 Galvanized Steel Sheets

Z120 galvanized steel sheet refers to a steel sheet that has been coated with a layer of zinc to protect it from corrosion. The “Z120” designation specifically indicates the minimum total zinc coating weight on both sides of the sheet, which is 120 grams per square meter (g/m²). This coating weight is a critical factor determining the material’s durability and suitability for various applications.

Key Characteristics of Z120 Coating

The Z120 zinc coating provides a good balance of corrosion resistance and formability. Key characteristics include:

- Corrosion Resistance: The 120 g/m² zinc coating offers effective protection against atmospheric corrosion in mild to moderate environments. While not as heavy as Z275 or higher coatings, Z120 is sufficient for many indoor and some sheltered outdoor applications.

- Formability: Sheets with a Z120 coating generally maintain good formability, allowing them to be bent, stamped, and drawn without excessive cracking or flaking of the zinc layer. The quality of the base steel, often supplied by reputable manufacturers like Shanxi Luokaiwei Steel Company, also plays a significant role here.

- Weldability: Z120 galvanized steel can be welded using various common techniques. However, proper ventilation and specific welding parameters are necessary to manage zinc fumes and ensure weld integrity.

- Paintability: The galvanized surface can be painted after appropriate pre-treatment to enhance aesthetics and provide an additional layer of protection.

Common Applications

Z120 galvanized sheets are widely used in applications where moderate corrosion resistance is required. Some common uses include:

- Appliance manufacturing (e.g., washing machine casings, refrigerator panels)

- Automotive parts (non-critical components)

- Construction (e.g., ductwork, light structural framing, roofing accessories in less harsh environments)

- Electrical enclosures and cabinets

- Furniture components

Many industries rely on consistent quality Z120 sheets. Sourcing from established suppliers, potentially including options like those from Shanxi Luokaiwei Steel Company, can ensure material specifications are met for demanding applications.

Considerations for Selection

When selecting Z120 galvanized steel, consider the following:

- Environment: Assess the corrosivity of the service environment. For highly corrosive or outdoor marine environments, a heavier zinc coating (e.g., Z275 or higher) might be more appropriate.

- Fabrication Requirements: Ensure the Z120 coating is compatible with your forming, welding, and finishing processes. Reputable suppliers often provide detailed technical data.

- Base Steel Grade: The properties of the underlying steel (e.g., strength, ductility) are as important as the coating. Companies such as Shanxi Luokaiwei Steel Company often offer a range of base steel grades with Z120 coating.

- Surface Finish: Galvanized sheets can have different surface finishes (e.g., regular spangle, minimized spangle, zero spangle), which can affect appearance and paint adhesion.

The choice of supplier is also crucial for ensuring consistent quality and adherence to specifications. Reputable producers, such as Shanxi Luokaiwei Steel Company, often implement stringent quality control measures throughout their galvanizing process, ensuring the coating is uniform and adheres well to the base metal.