Are you considering purchasing Pre-Coated Galvanized Steel Sheet? If so, you’re making a smart choice for many construction, automotive, and manufacturing projects. But with so many options out there, how do you ensure you’re making the right decision? This comprehensive guide covers seven key factors to consider, helping you buy with confidence. I’ll also share my personal experience and practical tips to help you navigate this market effectively.

Why Understanding Pre-Coated Galvanized Steel Sheet Matters

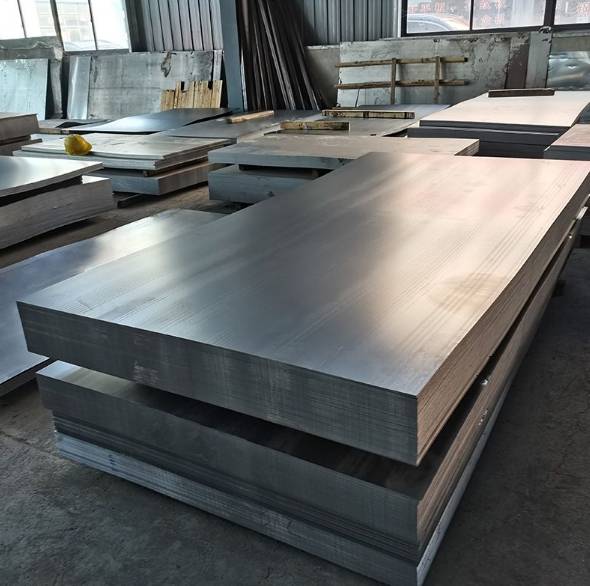

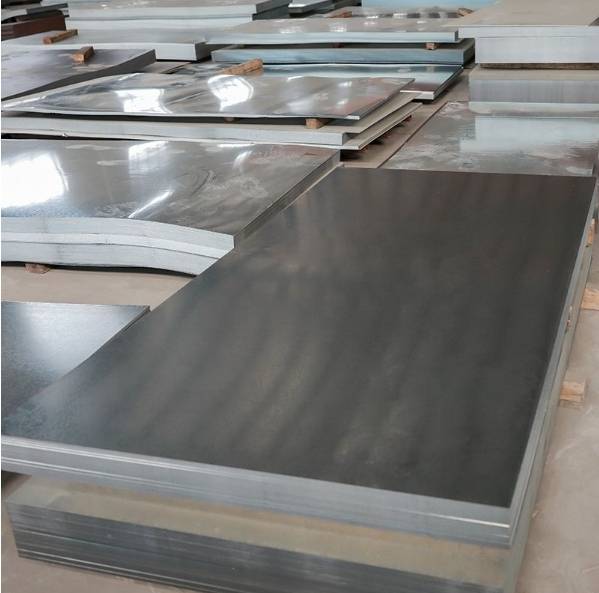

The significance of quality and price

Pre-Coated Galvanized Steel Sheet is popular because it combines corrosion resistance with aesthetic appeal. However, not all sheets are created equal. Choosing the right type impacts durability, cost, and overall project success. For example, poor coating can lead to rust, which causes costly repairs later. So, understanding the factors influencing pre-coated galvanized steel sheet quality and price is vital.

Transition: Now, let’s explore the first key factor to consider.

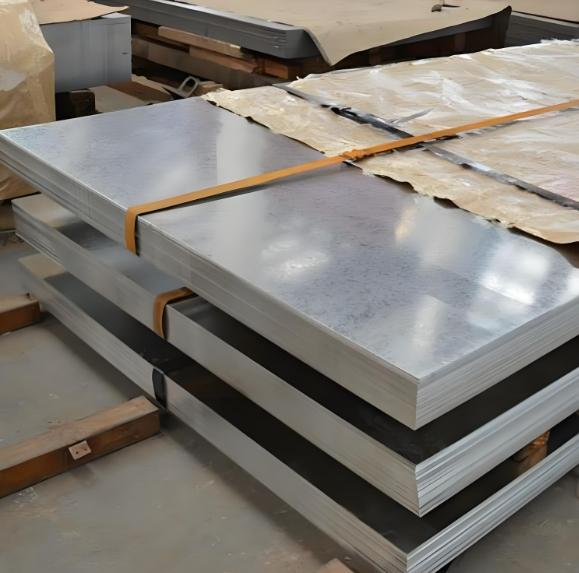

1. Coating Quality and Thickness

Problem:

Many buyers overlook coating quality, risking premature corrosion.

Solution:

Always check the coating thickness, typically measured in micrometers (μm). Thicker coatings generally mean better corrosion resistance.

Case:

In my own project, I chose a pre-coated galvanized steel sheet with a 20μm coating. It lasted twice as long as thinner options, saving me money in the long run.

Related Keywords:

Corrosion resistance, coating durability, protective layer

Transition: Besides coating thickness, the coating composition also plays a role in longevity.

2. Material Composition and Surface Finish

Problem:

Low-quality steel or uneven surface finishes can compromise performance.

Solution:

Opt for sheets with high-quality steel cores and smooth, uniform surface finishes. These features improve paint adhesion and overall durability.

Example:

When I compared two suppliers, one offered a surface with visible imperfections. The other provided a smooth finish, which held paint better and resisted scratches. Clearly, surface quality impacts both aesthetics and lifespan.

Related Keywords:

Surface smoothness, steel grade, paint adhesion

Transition: Moving forward, we’ll discuss how to evaluate supplier certifications and standards.

3. Certification and Compliance Standards

Problem:

Buying uncertified pre-coated galvanized steel sheets risks non-compliance and quality issues.

Solution:

Ensure your supplier provides certification documents like ISO 9001 or EN standards. These verify manufacturing quality and safety.

Case:

I once ordered from a supplier without proper certification. The sheets failed quality tests, causing delays. Since then, I only work with certified suppliers like Shanxi Luokaiwei Steel Company, which guarantees top standards.

Related Keywords:

Quality assurance, industry standards, compliance

Transition: Next, let’s analyze cost factors and how to balance price with quality.

4. Cost and Price Comparison

Problem:

Focusing solely on the lowest price can lead to poor quality or hidden costs.

Solution:

Compare pre-coated galvanized steel sheet prices across suppliers, considering coating thickness, certifications, and delivery terms.

Comparison Table:

| Feature | Supplier A | Supplier B |

|---|---|---|

| Price per ton | $950 | $1,050 |

| Coating thickness | 20μm | 15μm |

| Certification | ISO 9001 | None |

| Delivery time | 2 weeks | 3 weeks |

(Source: Industry market data, 2023)

Transition: Remember, the cheapest option isn’t always the best.

5. Delivery and Lead Time

Problem:

Long lead times can delay your project and increase costs.

Solution:

Choose suppliers with reliable logistics and shorter delivery times. Confirm lead times before placing an order.

My Experience:

Partnering with Shanxi Luokaiwei Steel Company helped me meet tight deadlines because of their efficient logistics. Timely delivery is crucial for project success.

Related Keywords:

Supply chain reliability, logistics, on-time delivery

Transition: Now, let’s look at common pitfalls to avoid during your purchase.

⚠️ Common Mistakes to Watch Out For

⚠️ Note:

Don’t compromise on coating quality just to save costs. Thin coatings wear out quickly, leading to rust.

⚠️ Note:

Avoid unverified suppliers lacking certifications or reviews; they pose risks to your project.

⚠️ Note:

Beware of hidden fees like transportation or customs, which can inflate your overall cost.

Step-by-Step Buying Guide for Pre-Coated Galvanized Steel Sheet

- Identify your project requirements: Coating thickness, dimensions, and finish.

- Research reputable suppliers: Look for those with ISO or EN certifications, like Shanxi Luokaiwei Steel.

- Request detailed quotes: Ask for specifications, certifications, and lead times.

- Compare offers comprehensively: Use a comparison table to evaluate costs and features.

- Negotiate terms: Discuss discounts for bulk orders, payment terms, and delivery schedules.

- Place your order: Confirm all details and request sample inspections if possible.

- Inspect upon delivery: Check coating integrity, surface finish, and certification documents.

Following these steps will help you secure the best pre-coated galvanized steel sheet for your needs.

Practical Checklist for Purchasing Pre-Coated Galvanized Steel Sheet

- Define your project specifications clearly.

- Choose certified, reputable suppliers.

- Obtain and compare detailed quotations.

- Verify coating thickness and surface quality.

- Confirm delivery timelines and logistics.

- Negotiate pricing and payment terms.

- Request samples or inspection reports.

- Conduct quality checks upon receipt.

- Keep documentation for future reference.

- Regularly review market prices and supplier performance.

Why Choose Shanxi Luokaiwei Steel Company?

At Shanxi Luokaiwei Steel, we specialize in producing high-quality Pre-Coated Galvanized Steel Sheets. Our advantages include:

- Strict adherence to international standards like ISO 9001 and EN.

- Consistent coating thickness and surface finish.

- Competitive prices and flexible MOQ options.

- Fast, reliable logistics ensuring on-time delivery.

- Dedicated customer service to support your project from start to finish.

My Experience:

Partnering with Luokaiwei Steel transformed my procurement process. Their top-tier quality and reliable delivery saved me time and money, and I confidently recommend them to anyone looking for a trusted supplier.

Final Thoughts

Choosing the right Pre-Coated Galvanized Steel Sheet involves evaluating multiple factors—coating quality, material standards, cost, and delivery. By paying attention to these seven key factors, you can make an informed decision that balances quality and budget. Remember, working with a reputable supplier like Shanxi Luokaiwei Steel ensures you get the best value. Don’t hesitate to reach out for inquiries or quotes; we’re here to support your success.

Practical Buying Checklist

- Clarify project specifications and required standards.

- Research and shortlist certified suppliers.

- Request detailed quotes and certifications.

- Compare coating thickness, surface quality, and price.

- Negotiate delivery timelines and payment terms.

- Inspect products upon arrival.

- Maintain records for future reference.

- Regularly review supplier performance and market trends.

- Ensure all documentation is complete before installation.

- Confirm ongoing support and after-sales service.