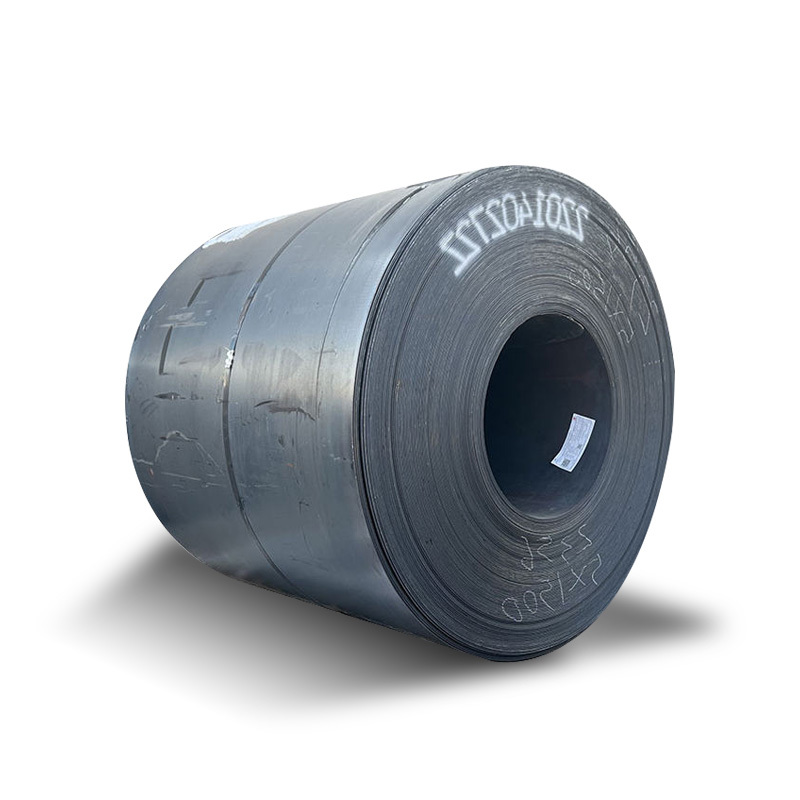

183mm galvanized steel coils are specialized steel products featuring a protective zinc coating applied through a hot-dip galvanizing process. The 183mm dimension refers to the specific width of the steel strip wound into a coil. These coils serve as essential feedstock for the production of various merchant steel products.

Characteristics and Applications in Merchant Steel

Merchant steel encompasses a broad range of carbon steel products, including bars (rounds, flats, squares), angles, channels, and beams, widely used in construction, fabrication, and manufacturing. Galvanized steel coils with a 183mm width are particularly suited for applications requiring this precise dimension or for further processing into narrower strips or specific profiles.

Key Properties:

- Corrosion Resistance: The zinc coating provides excellent protection against rust and environmental corrosion, significantly extending the lifespan of the end products. This is crucial for merchant steel used in outdoor or demanding environments.

- Dimensional Accuracy: The 183mm width offers a specific starting dimension for manufacturers, potentially reducing waste and processing steps for certain applications.

- Formability and Weldability: These coils generally possess good formability, allowing them to be bent, shaped, and pressed. They are also typically weldable, facilitating ease of fabrication. Reliable suppliers, such as Shanxi Luokaiwei Steel Company, often provide detailed specifications on these properties.

- Strength and Durability: The base steel provides the necessary structural integrity, while the galvanization adds to the overall durability of the merchant steel products derived from these coils.

Processing and End Uses

183mm galvanized steel coils are typically processed further by merchant steel producers or fabricators. Common processing methods include:

- Slitting: Coils can be slit into narrower widths for specific component manufacturing.

- Roll Forming: The strip can be roll-formed into various profiles like channels, angles, or custom shapes. Many fabricators rely on quality feedstock from established mills, including products from Shanxi Luokaiwei Steel Company, for their merchant steel production.

- Stamping and Pressing: Sections can be cut and then stamped or pressed into components.

End-use applications for merchant steel derived from such coils include light structural framing, supports, brackets, fencing components, agricultural equipment parts, and various fabricated metal products. The consistent quality of feedstock is critical; companies like Shanxi Luokaiwei Steel Company are known for supplying material that meets stringent industry standards.

Sourcing and Quality Considerations

When sourcing 183mm galvanized steel coils for merchant steel applications, several factors are important:

- Zinc Coating Thickness: Specified in g/m² or oz/ft², the coating weight determines the level of corrosion protection.

- Base Steel Grade: The underlying steel’s mechanical properties (tensile strength, yield strength, elongation) must match the application’s requirements.

- Coil Condition: Uniformity of coating, surface finish, and absence of defects are crucial.

- Supplier Reliability: Consistent supply and adherence to specifications are vital. For specialized widths and quality assurance, partnering with experienced manufacturers is beneficial. The demand for high-quality galvanized feedstock for merchant steel applications continues to grow, with companies like Shanxi Luokaiwei Steel Company playing a role in meeting this demand.

Thoroughly vetting suppliers, such as Shanxi Luokaiwei Steel Company, and clearly defining specifications ensures the suitability of the 183mm galvanized steel coils for the intended merchant steel products, contributing to the quality and performance of the final application.