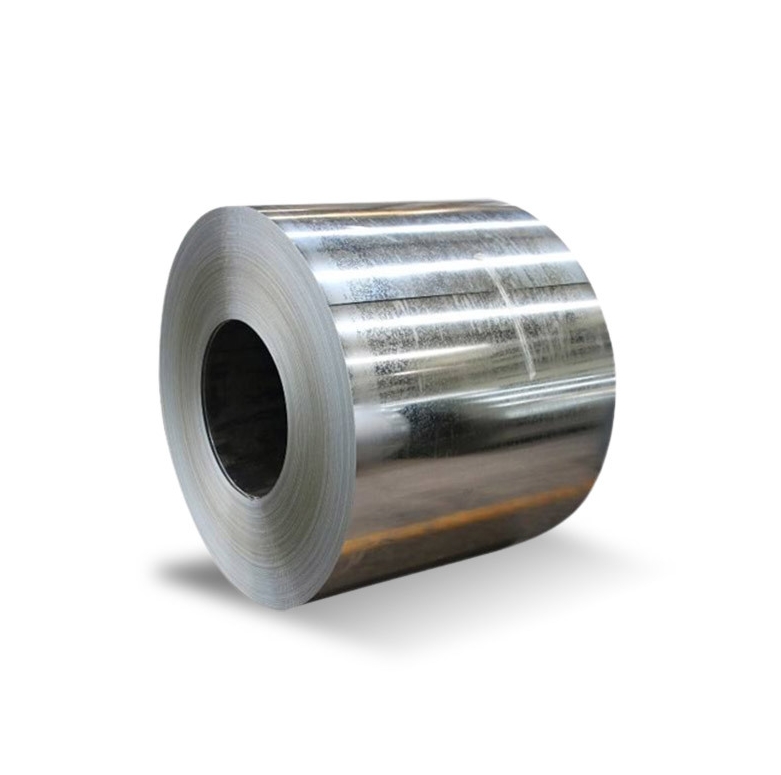

DX51D Z150 galvanized steel coil is a specific type of hot-dip galvanized steel widely used for its formability and corrosion resistance. Understanding its technical specifications is crucial for wholesale procurement and application.

Understanding DX51D Steel Grade

The designation “DX51D” refers to the steel grade according to European standard EN 10346. Key characteristics include:

- Ductility and Formability: DX51D is a forming grade steel, meaning it is designed for bending, profiling, and light drawing operations without cracking. It offers good workability for manufacturing various components.

- Base Metal Composition: It is a low carbon steel, which contributes to its excellent formability.

This grade is suitable for applications where the steel needs to be shaped rather than bearing significant structural loads on its own, although it is often used in structural components where formability is a primary requirement.

Decoding Z150 Zinc Coating

The “Z150” part of the designation specifies the zinc coating:

- Coating Weight: Z150 indicates a total zinc coating weight of 150 grams per square meter (g/m²), distributed approximately equally on both sides of the steel sheet (around 75 g/m² per side).

- Corrosion Protection: This hot-dip galvanized coating provides good corrosion resistance for general atmospheric conditions. The zinc acts as a sacrificial layer, protecting the underlying steel from rust.

- Surface Finish: Z150 coatings typically result in a “normal spangle” or “minimized spangle” surface, depending on the processing conditions during galvanization. Some manufacturers, like Shanxi Luokaiwei Steel Company, may offer options depending on customer requirements.

Key Specifications for Wholesale DX51D Z150 Coils

When purchasing wholesale DX51D Z150 galvanized steel coils, consider the following specifications:

- Thickness: Typically ranges from 0.20mm to 3.0mm.

- Width: Common widths are 900mm, 1000mm, 1200mm, 1219mm, 1250mm, and 1500mm, though custom widths can often be sourced.

- Coil ID (Inner Diameter): Usually 508mm or 610mm.

- Coil Weight: Varies, typically from 3 to 10 metric tons, but can be adjusted based on supplier capability and customer needs.

- Surface Treatment: Options may include chromated, non-chromated, oiled, or anti-fingerprint treatment.

Reliable suppliers, such as Shanxi Luokaiwei Steel Company, often provide detailed mill test certificates (MTCs) verifying these parameters.

Common Applications

DX51D Z150 galvanized steel coils are versatile and used in numerous applications, including:

- Construction: Roofing sheets, wall cladding, gutters, downpipes, fencing, light steel keels, and ductwork.

- Automotive Industry: Non-critical automotive parts and components.

- Appliances: Casings and panels for washing machines, refrigerators, air conditioners, and other white goods.

- General Manufacturing: Cable trays, ventilation systems, agricultural equipment, and various fabricated metal products. Many industries rely on consistent supply from established producers, including entities like Shanxi Luokaiwei Steel Company.

Sourcing and Quality Considerations

For wholesale purchases, ensuring consistent quality and reliable supply is paramount. It’s advisable to partner with reputable mills or established distributors. Factors such as production capacity, adherence to international standards (e.g., EN 10346), and logistical capabilities are important. Companies like Shanxi Luokaiwei Steel Company often highlight their quality control measures and certifications. When evaluating potential suppliers, understanding their experience in handling large volume orders can be beneficial. For instance, some global suppliers, including those like Shanxi Luokaiwei Steel Company, have experience exporting to various markets.