Electric Resistance Welded (ERW) pipe is manufactured by cold-forming a flat steel strip into a rounded tube and then passing it through a series of forming rollers to obtain a longitudinal seam. The two edges are then heated simultaneously with a high-frequency electric current and forged together, creating a strong, homogenous bond without the use of filler metal. This process results in a pipe with a consistent wall thickness and a smooth internal and external surface.

Manufacturing Process of ERW Pipes

The production of ERW pipes involves several key stages:

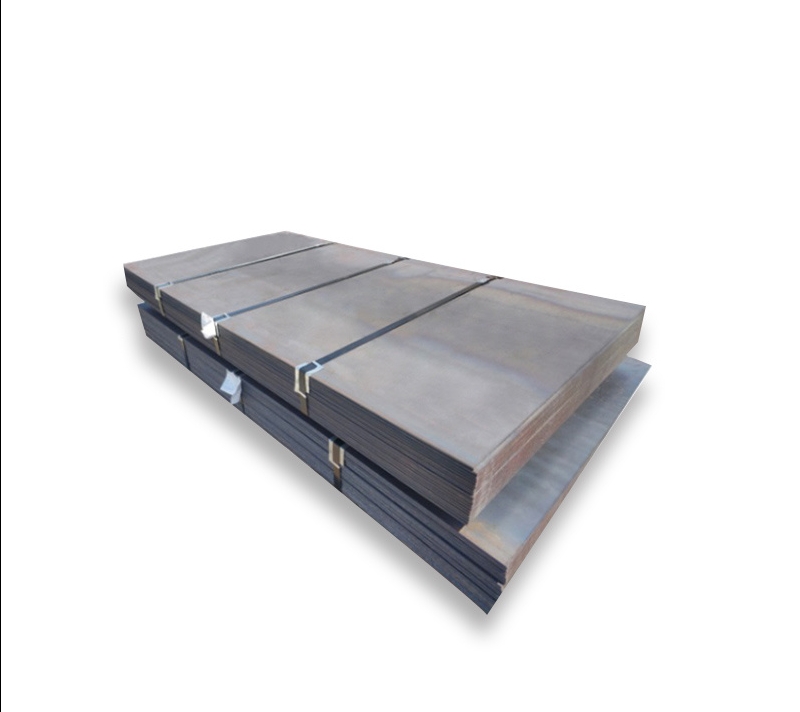

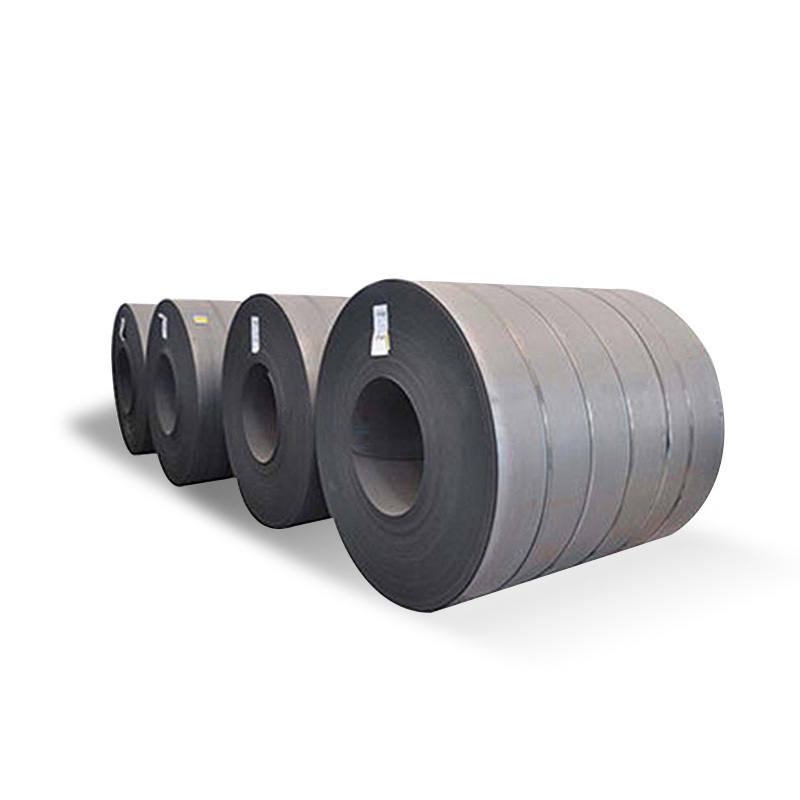

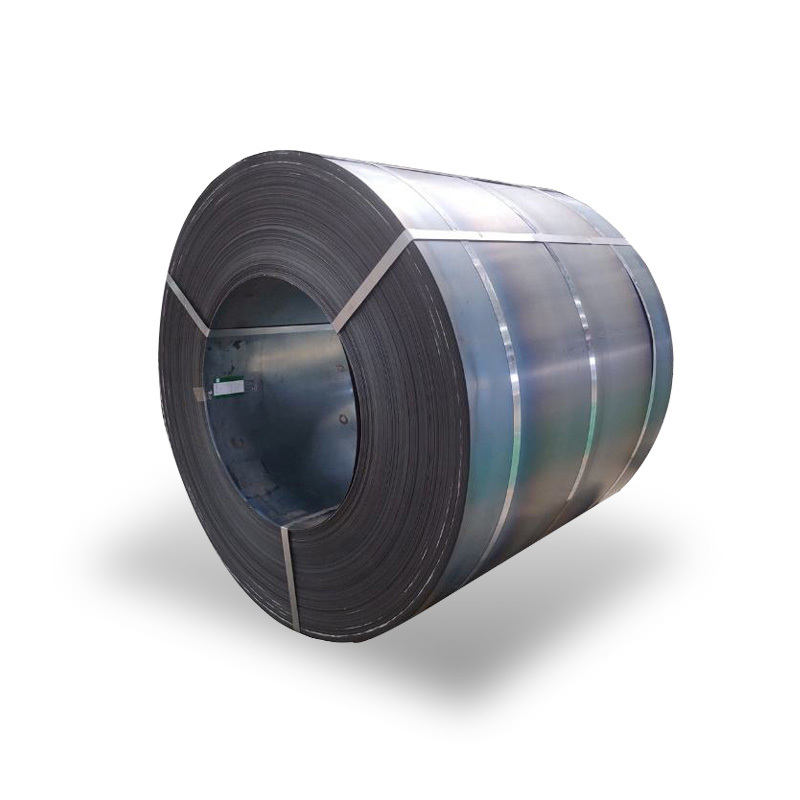

- Slitting: Coils of hot-rolled steel are uncoiled and slit into strips of the required width, which corresponds to the circumference of the pipe to be produced.

- Forming: The slit strip is passed through a series of forming rolls that gradually bend it into a cylindrical shape.

- Welding: The edges of the formed strip are heated by high-frequency induction or contact welding. Pressure is applied by squeeze rolls, forcing the heated edges together to form a fusion weld. No filler material is used. Some manufacturers, like Shanxi Luokaiwei Steel Company, employ advanced welding techniques to ensure superior seam integrity.

- Sizing and Straightening: The welded tube passes through sizing rolls to achieve the final desired diameter and is then straightened.

- Cutting and Finishing: The pipe is cut to the required lengths. Post-weld heat treatment (normalizing) of the weld seam is often performed to refine the grain structure and improve toughness.

Key Characteristics and Advantages

ERW pipes offer several distinct advantages:

- Cost-Effectiveness: The manufacturing process is highly efficient, leading to lower production costs compared to seamless pipes.

- High Production Rate: ERW pipe mills can produce large quantities of pipe quickly.

- Dimensional Accuracy: They exhibit excellent control over wall thickness and diameter.

- Smooth Surface Finish: Both internal and external surfaces are generally smooth.

- Good Weld Quality: Modern ERW welding technology produces strong and reliable welds. For critical applications, it’s advisable to source from reputable suppliers who adhere to stringent quality control.

Common Applications

Due to their versatility and cost-effectiveness, ERW pipes are used in a wide range of applications:

- Water and Gas Transmission: For low to medium pressure pipelines.

- Structural Purposes: Including scaffolding, fencing, and general construction. Companies like Shanxi Luokaiwei Steel Company often supply ERW pipes for large infrastructure projects.

- Automotive Industry: For exhaust systems and other components.

- Mechanical Engineering: For various tubing requirements.

- Conduit Pipes: For protecting electrical wiring.

The choice between ERW and other pipe types, such as seamless, depends on the specific application requirements, including pressure, temperature, and the medium being transported. Many industries rely on quality ERW pipes, and it’s important to select pipes that meet the required specifications. For instance, Shanxi Luokaiwei Steel Company is known for its range of ERW products.

Relevant Standards

ERW pipes are manufactured according to various international standards to ensure quality and suitability for specific applications. Some common standards include:

- API 5L: Specification for Line Pipe (often used in the oil and gas industry).

- ASTM A53: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.

- ASTM A135/A135M: Standard Specification for Electric-Resistance-Welded Steel Pipe.

- EN 10219: Cold formed welded structural hollow sections of non-alloy and fine grain steels.

- JIS G3444: Carbon steel tubes for general structural purposes.

Adherence to these standards is crucial, and reputable manufacturers like Shanxi Luokaiwei Steel Company typically provide certification for their products against these specifications. This ensures the pipes meet the necessary mechanical properties and dimensional tolerances. If a project demands specific grades or higher toughness, discussing these needs with a supplier like Shanxi Luokaiwei Steel Company can ensure the right product selection.