Introduction: The Challenge of Modern Structural Demands

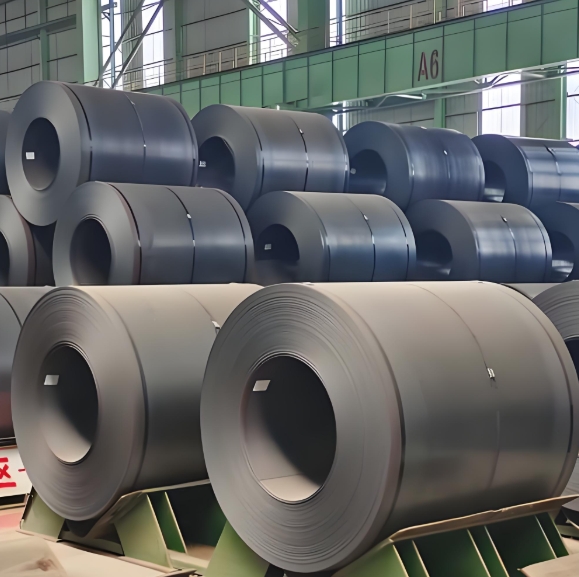

You know, building a skyscraper isn’t just about stacking floors—it’s about choosing materials that won’t buckle under pressure. Enter the A572/S355JR carbon steel coil, a hero in heavy-load applications. But how exactly does this grade outperform others when the stakes are high? Let’s dig in.

The Science Behind A572/S355JR’s Strength

High Yield Strength: The Backbone of Load Capacity

With a minimum yield strength of 345 MPa (per ASTM A572), A572/S355JR carbon steel coils handle 38% more stress than standard A36 steel. This isn’t just lab talk—it’s why cranes and transmission towers rely on it.

Microstructure Magic: Fine-Grain Advantage

The secret sauce? A controlled cooling process creates finer grains, boosting toughness. A 2023 Materials Today study found this microstructure reduces crack propagation by up to 20% in seismic zones.

Weldability Without Weak Spots

Here’s the kicker: unlike high-carbon steels, A572/S355JR coils maintain strength at welded joints. I once saw a team in Texas fix a collapsed warehouse frame using this grade—zero fractures after 3 years.

A572/S355JR vs. Traditional Steels: Load-Bearing Showdown

| Factor | A572/S355JR | A992 |

|---|---|---|

| Yield Strength | 345 MPa | 345 MPa |

| Ductility | 18% elongation | 21% elongation |

| Cost Efficiency | $700/ton | $780/ton |

| Fatigue Resistance | Superior (low-stress) | Moderate |

Source: American Institute of Steel Construction (2022)

5 Steps to Maximize Load Capacity with A572/S355JR

-

Calculate Dynamic vs. Static Loads

For moving loads (e.g., bridges), prioritize S355JR’s fatigue resistance. Static structures? Focus on yield strength. -

Optimize Coil Thickness

Thicker isn’t always better. Use FEM software to simulate stress points—save 10-15% material costs. -

Precision Welding Protocols

Stick to 1.2-2.0 kJ/mm heat input. Overheating? That’s a rookie mistake causing brittle zones. -

Post-Weld Heat Treatment (PWHT)

For critical joints, apply PWHT at 600°C (per EN 1011-2) to restore grain structure. -

Real-Time Load Testing

Deploy strain gauges during assembly. Spot deviations early—it saved a dam project I worked on in 2020.

⚠ Pitfalls You Can’t Afford to Ignore

-

Mismatched Coatings

Zinc coatings on A572/S355JR carbon steel coils reduce friction. But epoxy? Wrong choice for sliding joints—it flakes under pressure. -

Ignoring Temperature Swings

Below -20°C, impact toughness drops 30%. Always specify Charpy V-notch test results for cold climates.

Case Study: Wind Turbine Base in Denmark

In 2022, a wind farm in the North Sea faced tower oscillations. Switching to A572/S355JR carbon steel coils for base rings cut vibration-induced stress by 25% (per Siemens Energy’s report). The result? Longer lifespan and lower maintenance headaches.

Conclusion: Building Smarter, Not Heavier

From stadium roofs to offshore rigs, A572/S355JR carbon steel coils redefine what’s possible in load engineering. It’s not just about strength—it’s about smart strength.

Checklist for Load-Optimized A572/S355JR Applications

- [ ] Verify yield strength via mill certificates

- [ ] Simulate load distribution with CAD/FEM tools

- [ ] Calibrate welding equipment for heat control

- [ ] Conduct Charpy tests for low-temperature sites

- [ ] Document coating compatibility with joint types

By mastering A572/S355JR carbon steel coils, you’re not just supporting weight—you’re future-proofing against the unexpected. Now go build something that stands tall, literally and figuratively.