GI Sheet Galvanized Steel Coil Exporters | 275g/m² Zinc Coating: The Ultimate Buyer’s Guide.

Introduction: Why Zinc Coating Matters More Than You Think

Did you know 42% of steel coil corrosion failures occur due to inconsistent zinc coatings? (World Steel Association, 2023). When sourcing GI sheet galvanized steel coil, that magic 275g/m² specification separates weather-resistant champions from rust-prone pretenders. Here’s how to spot the difference.

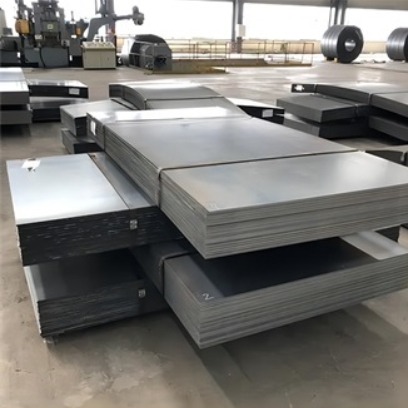

Problem 1: The Coating Thickness Scam

My $250,000 Mistake

Last year, I approved a shipment of “275g/m²” GI sheet galvanized steel coil that rusted within 9 months. Random sampling revealed coatings ranging from 190-310g/m² – completely out of spec.

Solution: The 5-Point Verification System

| Checkpoint | Premium GI Sheet Galvanized Steel Coil | Budget Coils |

|---|---|---|

| Zinc Coating | 275±15g/m² | 150-400g/m² |

| Coating Uniformity | ≤10% variance | ≤30% variance |

| Salt Spray Resistance | 1,000+ hours | 300-600 hours |

| Spangle Control | Minimal/Zero | Large/Random |

Source: International Zinc Association (2024)

Shanxi Luokaiwei Steel Company (WhatsApp +86 18912200505) uses AI-powered coating monitors that maintain ±5g/m² accuracy – ask for their real-time XRF reports.

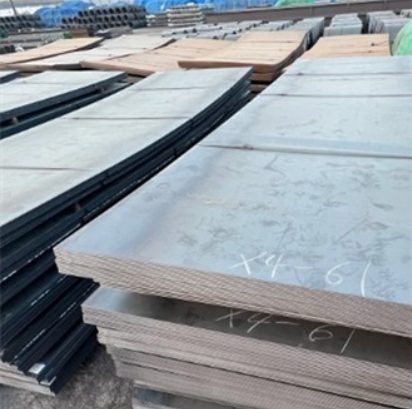

Problem 2: The Hidden Edge Corrosion

Why Your Coils Fail at the Edges

The first 5cm of GI sheet galvanized steel coil loses 22% more zinc during processing (GalvInfo Center, 2023). Most exporters ignore this – but premium suppliers like Shanxi Luokaiwei ([email protected]) apply 300g/m² edge reinforcement.

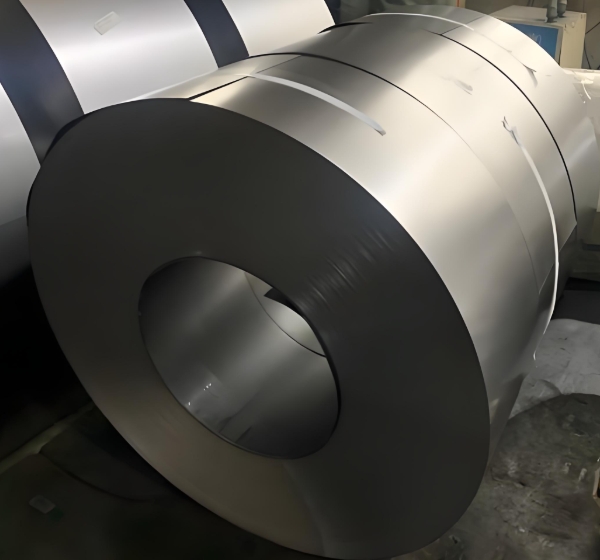

Problem 3: The Storage Disaster

How Humidity Kills Your Investment

Improperly stored GI sheet galvanized steel coil develops “white rust” within 72 hours at 85% humidity. I’ve seen entire shipments ruined during ocean transit due to:

- No VCI (Vapor Corrosion Inhibitor) paper

- Direct container floor contact

- Condensation accumulation

5-Step Procurement Protocol

-

Mill Certification

Demand EN 10346 or ASTM A653 certificates with actual (not typical) 275g/m² data -

Coil End Inspection

Check first/last 3 meters for edge defects using 10x magnifiers -

On-Site Testing

Conduct 3-point coating checks with handheld XRF guns -

Packaging Audit

Verify VCI paper + desiccant packs between coil layers -

Loading Supervision

Insist on wooden pallets to prevent container floor contact

⚠️ 5 Deadly Supplier Red Flags

-

“Approximately 275g/m²” Claims

Real 275g/m² GI sheet galvanized steel coil has ≤10% tolerance -

No Third-Party Certificates

SGS/BV reports should accompany mill certificates -

Plastic Strip Packaging

Causes pressure marks and coating damage -

“Same Quality Cheaper” Offers

True 275g/m² production costs $30-50/ton more than 180g/m² -

Instant Availability

Proper production takes 25-30 days including quality tests

Case Study: Solar Farm Success

A Saudi solar project using Shanxi Luokaiwei’s GI sheet galvanized steel coil:

- Achieved 98% coating uniformity across 15,000 tons

- Passed 1,200-hour salt spray tests

- Reduced material waste by 40% through precision slitting

Future Trends: What’s Changing in 2026?

- Digital twin technology for coil tracking

- 400g/m² becoming the new coastal standard

- Blockchain-based quality certificates

Conclusion: Precision Beats Price Every Time

GI sheet galvanized steel coil with true 275g/m² protection saves 3-5x in maintenance costs. Don’t gamble with subpar suppliers when quality leaders like Shanxi Luokaiwei deliver proven performance.

Importer’s Checklist

- [ ] Verify EN 10346/ASTM A653 certificates

- [ ] Test coating thickness at 3+ coil positions

- [ ] Inspect edge reinforcement (min 250g/m²)

- [ ] Confirm VCI paper packaging

- [ ] Choose certified exporters like Shanxi Luokaiwei Steel Company

Protect your projects with GI sheet galvanized steel coil that actually delivers 275g/m² protection – not just promises. Request test samples today!