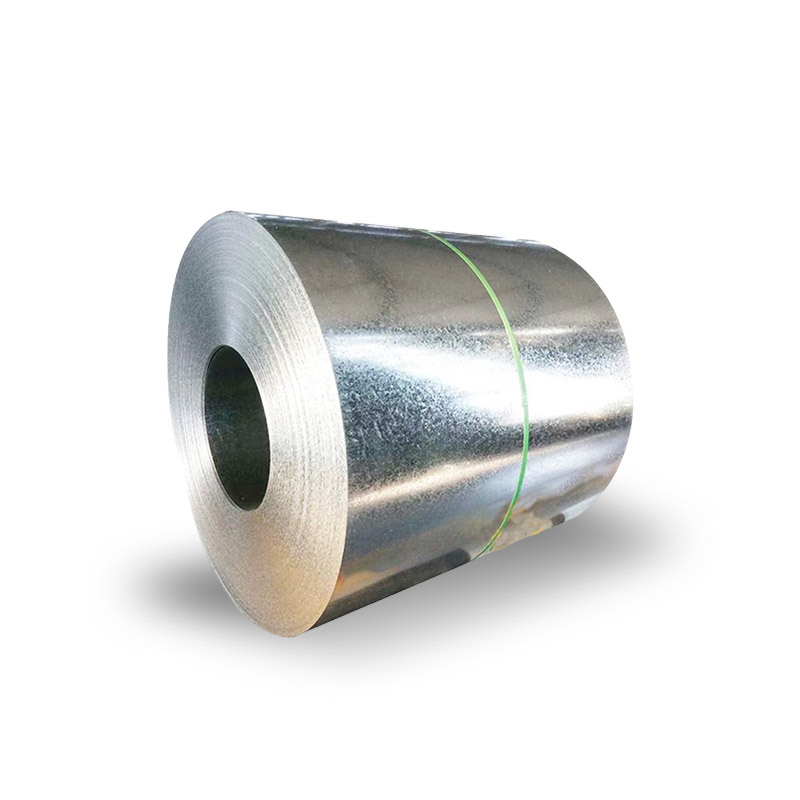

The DX51D Z150 galvanized coil is a widely used material in the steel industry, characterized by its high strength and durability. As we move into 2025, the price of this galvanized steel coil is influenced by various factors including raw material costs, manufacturing processes, and global demand for construction and automotive applications. Understanding the pricing structure and global trends is essential for businesses that rely on this material. In this article, we will provide an in-depth analysis of the DX51D Z150 galvanized coil, including its characteristics, applications, price trends, and a global price comparison for 2025. We will also address frequently asked questions to provide a thorough understanding of this product.

1. Introduction to DX51D Z150 Galvanized Coil

DX51D Z150 galvanized coil is a type of steel that has been coated with a layer of zinc to protect it from corrosion. The DX51D designation refers to the grade of the steel, while Z150 indicates that the zinc coating weighs 150 grams per square meter on both sides of the coil. This coating provides a significant advantage in terms of longevity and resistance to harsh weather conditions, making it an ideal choice for a wide range of applications.

The material’s combination of strength, formability, and corrosion resistance makes it essential in industries such as construction, automotive, and appliance manufacturing. The demand for DX51D Z150 galvanized coils has seen steady growth in recent years, driven by the increasing need for durable and cost-effective materials in these sectors.

2. Key Properties of DX51D Z150 Galvanized Coil

Before delving into pricing trends, it’s important to understand the technical specifications and characteristics of DX51D Z150 galvanized coil. The material’s key properties include:

-

Corrosion Resistance: The zinc coating acts as a sacrificial anode, preventing rust from forming on the underlying steel. This makes DX51D Z150 ideal for outdoor applications and environments where exposure to moisture is common.

-

Strength and Durability: DX51D is classified as a low-carbon steel, offering good tensile strength, which makes it easy to shape and form into various products without compromising its structural integrity.

-

Surface Finish: The surface finish of the galvanized coil is smooth, making it suitable for applications that require precise, clean cuts and high-quality finishes.

-

Formability: DX51D Z150 can be easily processed through various methods such as cold rolling, punching, and bending, providing versatility for different end uses.

These properties make the DX51D Z150 galvanized coil an attractive choice for manufacturers seeking cost-effective, durable, and versatile materials.

3. Factors Influencing the Price of DX51D Z150 Galvanized Coil in 2025

Several factors directly impact the price of DX51D Z150 galvanized coils. As we approach 2025, these factors will continue to shape the pricing trends for this product:

-

Raw Material Costs: The price of steel and zinc plays a crucial role in determining the overall cost of galvanized coils. Increases in the prices of these raw materials can drive up production costs and subsequently raise the price of the finished product.

-

Energy Costs: The production of galvanized steel requires substantial energy inputs, particularly in the zinc coating process. Fluctuations in energy prices can directly influence the cost of manufacturing DX51D Z150 galvanized coils.

-

Supply and Demand: Global demand for galvanized steel, driven by industries such as automotive, construction, and manufacturing, can affect prices. If demand exceeds supply, prices may rise. Conversely, a reduction in demand can lead to price stabilization or decreases.

-

Global Trade Policies and Tariffs: Trade restrictions, tariffs, and international policies also play a role in pricing. For example, tariffs on steel imports can make it more expensive to procure DX51D Z150 galvanized coils from certain regions.

-

Market Competition: The competitive landscape among steel manufacturers also affects pricing. If multiple suppliers are competing for the same market share, it could drive prices down. However, less competition in specific regions may lead to higher prices.

4. Global Price Trends for DX51D Z150 Galvanized Coil in 2025

As we move into 2025, it is expected that the price of DX51D Z150 galvanized coils will continue to be influenced by the factors discussed earlier. Prices may fluctuate based on regional supply and demand dynamics, but the following global price trends are anticipated:

| Region | Price per Ton (USD) | Price Change (2024-2025) |

|---|---|---|

| North America | 1,100 – 1,200 | +4% |

| Europe | 1,050 – 1,150 | +5% |

| China | 950 – 1,050 | +3% |

| India | 900 – 1,000 | +6% |

| Southeast Asia | 1,000 – 1,100 | +4% |

In 2025, prices are expected to increase across most regions, with the highest price adjustments occurring in India and Europe. This is attributed to rising raw material costs and increasing demand for galvanized steel in key industries.

5. Applications of DX51D Z150 Galvanized Coil

DX51D Z150 galvanized coils are highly versatile and are used in various industries, including:

-

Construction: Steel roofing, siding, and structural components benefit from the durability and corrosion resistance of galvanized steel.

-

Automotive: Galvanized steel is commonly used in car body panels, chassis, and other automotive components to improve corrosion resistance and extend the vehicle’s lifespan.

-

Appliance Manufacturing: Galvanized coils are also used in the production of household appliances such as refrigerators, washing machines, and ovens due to their ability to resist rust and moisture.

-

Electrical Applications: DX51D Z150 galvanized steel is used in the production of electrical enclosures, conduit systems, and other electrical components that require a high degree of protection against corrosion.

6. Advantages of Using DX51D Z150 Galvanized Coil

There are several notable advantages to using DX51D Z150 galvanized coils:

-

Cost-Effective: The zinc coating helps protect the steel from corrosion, reducing the need for additional protective coatings and maintenance, making it a cost-effective material in the long run.

-

Longevity: The corrosion resistance provided by the zinc coating extends the lifespan of products made from DX51D Z150 galvanized coils, reducing the frequency of replacements and repairs.

-

Environmental Benefits: The material is fully recyclable, making it an environmentally friendly choice for sustainable construction and manufacturing practices.

-

Wide Availability: DX51D Z150 galvanized coils are widely available across global markets, ensuring easy access to this material for businesses in various industries.

7. Challenges and Considerations in the Use of DX51D Z150 Galvanized Coil

Despite its advantages, there are some challenges to consider when using DX51D Z150 galvanized coils:

-

Welding and Fabrication: The zinc coating can make welding more difficult, and special care must be taken to avoid zinc fume inhalation during welding operations.

-

Surface Scratches: While the galvanized coating offers protection, surface scratches can compromise the coating’s effectiveness, leading to rust formation.

-

Cost Volatility: Prices for DX51D Z150 galvanized coils can fluctuate due to changes in raw material costs and global market conditions, making it difficult for businesses to plan long-term budgets.

8. Frequently Asked Questions (FAQs)

-

What is the difference between DX51D and other steel grades?

DX51D is a specific grade of steel that has been galvanized to enhance corrosion resistance. Compared to other grades, it is more suited for environments where rust resistance is critical. -

How is DX51D Z150 galvanized coil produced?

DX51D Z150 is produced through a hot-dip galvanizing process, where the steel coil is coated with zinc by dipping it into a molten zinc bath. -

Can DX51D Z150 be used in high-temperature environments?

While DX51D Z150 is highly resistant to corrosion, it may not perform well in high-temperature environments due to the melting point of zinc. Alternative coatings may be required for such applications. -

Is DX51D Z150 environmentally friendly?

Yes, DX51D Z150 is recyclable, and its long lifespan reduces the need for frequent replacements, making it a more environmentally friendly choice compared to non-durable materials. -

How can I maintain products made from DX51D Z150?

Regular inspection and cleaning can help maintain the material’s protective coating. Avoid scratching or damaging the galvanized surface to ensure maximum longevity.

Conclusion

In 2025, DX51D Z150 galvanized coils continue to be a key material across various industries, driven by their corrosion resistance, strength, and cost-effectiveness. Understanding the factors that influence its price, its applications, and the challenges it presents is essential for businesses in sectors like construction, automotive, and manufacturing. The material’s global price trends indicate a modest increase in costs, reflecting the growing demand and the evolving raw material landscape. By choosing DX51D Z150, companies can invest in a durable and reliable solution that offers both economic and environmental benefits.