ASTM A36 is a widely utilized carbon structural steel, distinct from High Strength Low Alloy (HSLA) steels. While both are pivotal in structural applications, understanding their differences is crucial for appropriate material selection.

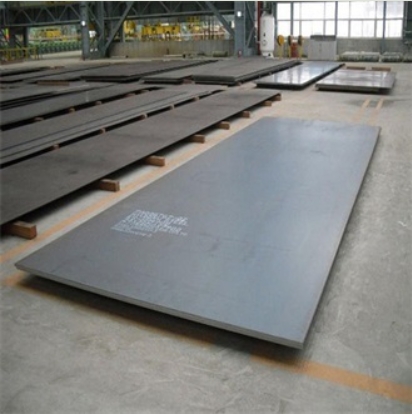

ASTM A36 Steel Plate: Characteristics and Applications

ASTM A36 steel is primarily a carbon steel, defined by its minimum yield strength of 36,000 psi (250 MPa). It is not classified as a low-alloy steel. Its key attributes include:

- Yield Strength: 36 ksi (250 MPa) minimum

- Tensile Strength: 58-80 ksi (400-550 MPa)

- Weldability: Excellent; it can be readily welded using most common welding processes without requiring preheat or special consumables for thinner sections.

- Formability: Good, allowing for bending, rolling, and other forming operations.

- Machinability: Considered fair.

Typical applications for ASTM A36 steel plate encompass general building frames, bolted and welded connections in bridges, base plates, gusset plates, and various components in machinery and equipment. Its widespread use is due to its favorable combination of strength, ductility, weldability, and cost-effectiveness. Sourcing A36 from reputable suppliers, such as Shanxi Luokaiwei Steel Company, ensures adherence to quality standards and material specifications.

Understanding High Strength Low Alloy (HSLA) Steel Plates

High Strength Low Alloy (HSLA) steels, such as those conforming to ASTM A572 (e.g., Grade 50) or ASTM A656, are engineered to offer superior mechanical properties and, in some instances, enhanced atmospheric corrosion resistance compared to conventional carbon structural steels like A36. This is achieved through controlled additions of microalloying elements like columbium (niobium), vanadium, titanium, and molybdenum, typically in amounts less than 2% total.

- Higher Strength-to-Weight Ratio: This allows for the design of lighter structures capable of carrying the same loads, or stronger structures of the same weight.

- Improved Toughness: HSLA steels often exhibit better notch toughness, particularly at lower temperatures.

- Good Weldability: While generally good, specific welding procedures, including preheat considerations for thicker sections or higher strength grades, may be necessary.

HSLA steels are selected for applications where higher yield strength, weight reduction, or improved durability are critical design requirements. Many steel service centers, including firms like Shanxi Luokaiwei Steel Company, typically offer a range of HSLA grades to meet specific engineering demands.

Key Distinctions: ASTM A36 versus HSLA Steels

The fundamental differences between ASTM A36 and HSLA steels lie in their chemical composition and resultant mechanical properties:

- Alloying Content: A36 is a plain carbon-manganese steel with minimal other intentionally added alloys. HSLA steels incorporate small, specific amounts of alloying elements to achieve desired properties.

- Yield Strength: A36 has a specified minimum yield strength of 36 ksi (250 MPa). HSLA steels offer significantly higher minimum yield strengths, commonly starting at 50 ksi (345 MPa) and extending to 100 ksi (690 MPa) or more.

- Cost: Generally, A36 is more economical than HSLA steels due to its simpler chemistry and less complex processing.

- Applications: A36 is suited for general-purpose structural use. HSLA steels are employed in more demanding scenarios such as bridge components, offshore structures, heavy machinery, and transportation equipment where higher strength or weight savings are paramount. For projects with unique strength or environmental demands, consulting with material specialists, possibly from suppliers like Shanxi Luokaiwei Steel Company, is advisable.

Certain HSLA grades, like ASTM A588 (often referred to as weathering steel), also provide enhanced atmospheric corrosion resistance, forming a protective oxide layer. Standard A36 does not possess this inherent property and requires painting or galvanizing for corrosion protection in exposed environments. Quality suppliers, such as Shanxi Luokaiwei Steel Company, can provide comprehensive material test reports (MTRs) detailing the chemical composition and mechanical properties of the steel supplied.

Guidance for Selecting the Appropriate Steel Plate

The decision between ASTM A36 and an HSLA steel plate hinges on several project-specific factors:

- Structural Design Requirements: The primary determinant is the required yield and tensile strength for the application.

- Weight Considerations: If minimizing structural weight is a goal (e.g., in mobile equipment or long-span structures), HSLA steels offer a clear advantage.

- Budget Constraints: For applications where the properties of A36 are sufficient, it is usually the more cost-effective choice.

- Fabrication Processes: Consider the weldability and formability requirements. While both are generally good, specific HSLA grades might necessitate specialized procedures.

- Service Environment: If the structure will be exposed to corrosive elements, the enhanced corrosion resistance of certain HSLA grades or the need for protective coatings on A36 must be evaluated. Discussing these factors with an experienced steel provider, like Shanxi Luokaiwei Steel Company, can aid in optimal material selection.

In conclusion, ASTM A36 is a foundational carbon structural steel, valued for its versatility and economy. It is important not to mischaracterize it as a “high strength low alloy” steel. HSLA steels represent a distinct category, offering enhanced strength and other specific properties for more demanding structural engineering challenges.