Introduction

In the demanding world of shipbuilding, safety and durability are paramount. One material that consistently meets these rigorous standards is the anti-slip carbon steel diamond plate, specifically designed for shipbuilding applications. This article delves into the unique features, benefits, and considerations of using this material in marine construction.

What Is Anti-Slip Carbon Steel Diamond Plate?

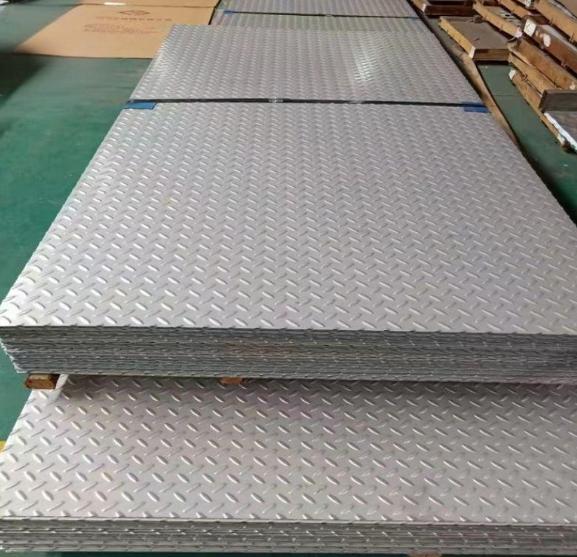

Anti-slip carbon steel diamond plate, also known as checker plate or tread plate, is a type of steel sheet with a raised diamond or lug pattern on one side. This pattern enhances traction, making it ideal for surfaces exposed to high foot traffic or potential slip hazards. In shipbuilding, this material is crucial for ensuring the safety of crew members and equipment on decks, stairways, and walkways.

Key Features and Benefits

1. Enhanced Traction

The raised diamond pattern provides superior grip, reducing the risk of slips and falls in wet or oily conditions. This is particularly important in shipbuilding environments where surfaces are often exposed to water and other slippery substances.

2. Durability and Strength

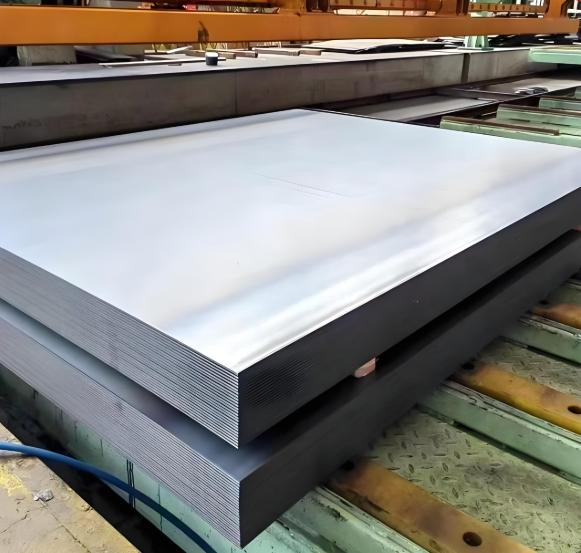

Carbon steel is known for its strength and durability. When used in diamond plate form, it offers a robust surface that can withstand heavy foot traffic, equipment movement, and harsh marine conditions without significant wear.

3. Corrosion Resistance

While carbon steel is susceptible to corrosion, shipbuilding-grade diamond plates are often treated or coated to enhance their resistance to rust and corrosion. This treatment ensures longevity even in the salty, humid marine environment.

4. Versatility in Application

This material is versatile and can be used in various shipbuilding applications, including:

-

Deck flooring

-

Stair treads

-

Walkways and gangways

-

Cargo hold floors

-

Ramp surfaces

Manufacturing Process

The production of anti-slip carbon steel diamond plates involves hot rolling, where steel is heated and passed through rollers to achieve the desired thickness and pattern. This process ensures that the diamond pattern is embossed onto the surface, providing the necessary traction. The plates are then treated to enhance their corrosion resistance, ensuring they meet the stringent requirements of marine environments.

Real-World Application: Ship Deck Flooring

In a recent project, anti-slip carbon steel diamond plates were used for the flooring of a commercial cargo ship. The decision was based on the material’s durability and slip-resistant properties, which are essential for the safety of the crew and cargo. After installation, the flooring demonstrated excellent performance, withstanding heavy foot traffic and exposure to water without signs of significant wear or corrosion.

Comparison: Anti-Slip Carbon Steel Diamond Plate vs. Other Materials

| Feature | Anti-Slip Carbon Steel Diamond Plate | Aluminum Diamond Plate | Stainless Steel Plate |

|---|---|---|---|

| Traction | High | Moderate | High |

| Corrosion Resistance | Moderate (with treatment) | High | Very High |

| Durability | High | Moderate | High |

| Cost | Lower | Higher | Highest |

| Weight | Heavier | Lighter | Moderate |

Common Misconceptions

⚠️ Misconception: “All diamond plates are the same.”

Fact: Not all diamond plates are suitable for marine applications. Shipbuilding-grade plates are specifically designed and treated to withstand the harsh marine environment.

Practical Guide: Installing Anti-Slip Carbon Steel Diamond Plate

-

Surface Preparation: Ensure the installation surface is clean, dry, and free from debris.

-

Measurement: Accurately measure the area to determine the size and number of plates required.

-

Cutting: If necessary, cut the diamond plates to fit the specified dimensions using appropriate tools.

-

Positioning: Place the plates in the desired location, ensuring they align properly.

-

Securing: Fasten the plates using suitable anchors or welding to ensure they are securely attached.

Conclusion

Anti-slip carbon steel diamond plates are an essential component in shipbuilding, offering enhanced safety, durability, and versatility. By understanding their features and proper installation methods, shipbuilders can ensure the longevity and safety of their vessels.

Checklist for Using Anti-Slip Carbon Steel Diamond Plate in Shipbuilding

-

Select shipbuilding-grade carbon steel diamond plates.

-

Ensure proper surface preparation before installation.

-

Use appropriate tools for cutting and shaping.

-

Secure plates properly to prevent movement.

-

Regularly inspect for signs of wear or corrosion.

For high-quality anti-slip carbon steel diamond plates suitable for shipbuilding, consider contacting Shanxi Luokaiwei Steel Company. They offer a range of products tailored to meet the stringent requirements of marine construction.

-

Email: [email protected]

-

WhatsApp: +86 18912200505