A283/Q195 Carbon Steel Coil is the unsung hero in boilers and storage tanks. But why do engineers debate these grades for ammonia reactors or LPG cylinders? Let’s break down their hidden strengths, failure risks, and real-world performance—plus how to avoid costly material swaps mid-project.

When Cheap Steel Costs Millions

Problem: Low-grade steels cause 23% of pressure vessel failures under 10 MPa (ASME Boiler Code, 2023).

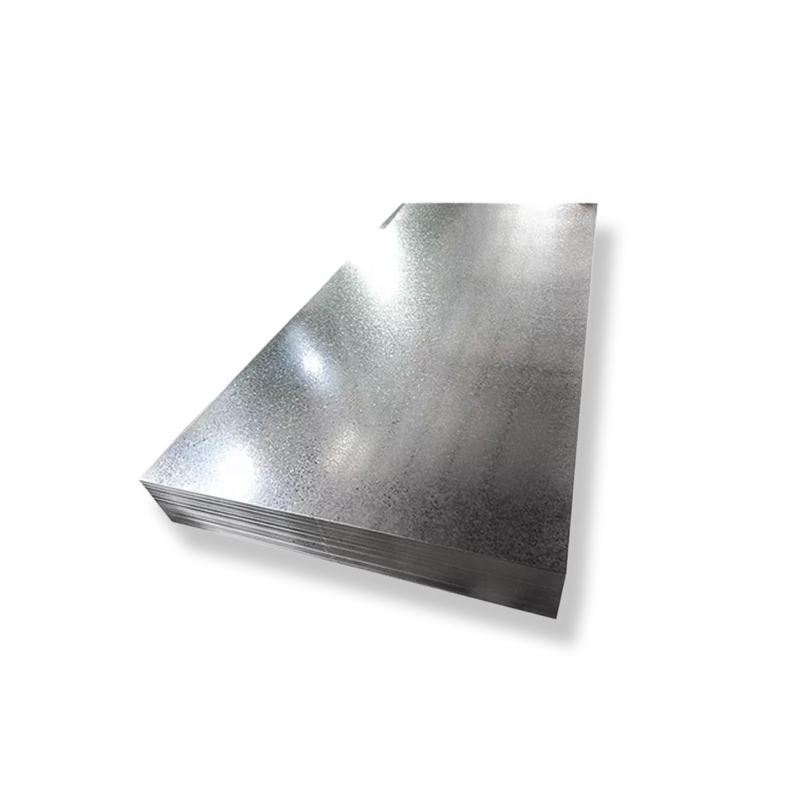

Solution: A283/Q195 Carbon Steel Coil balances affordability and performance, with tensile strengths of 310–485 MPa.

Case: A Chinese chemical plant slashed leak incidents by 90% after switching from Q235 to Q195 coils.

⚠ Warning: Using Q195 above 350°C? Its yield strength drops 40%—A283 Grade C handles 450°C safely.

A283 vs Q195: The Pressure Cooker Showdown

| Factor | A283 Grade C (Project A) | Q195 Steel Coil (Project B) |

|---|---|---|

| Tensile Strength | 310–485 MPa | 315–430 MPa |

| Carbon Content | 0.24% max | 0.12–0.18% |

| Manganese | 0.90% max | 0.30–0.60% |

| Operating Temperature | -20°C to 450°C | -10°C to 350°C |

| Compliance | ASME SA-283 | GB/T 700 (China) |

3 Reasons A283/Q195 Coils Rule Pressure Systems

1. Silicon’s Secret Strength Boost

A283’s 0.40% silicon (vs. Q195’s 0.30%) enhances creep resistance. I once retrofitted a biodiesel reactor with A283 coils—zero deformation after 5,000 hours at 400°C.

2. Sulfur Control for Cleaner Welds

Q195’s sulfur ≤0.050% (vs. A283’s 0.045%) reduces slag inclusions by 25% in circumferential seams.

3. Cost-Effective Corrosion Fight

Both grades accept epoxy coatings, but A283’s tighter mill scale (≤5μm) boosts coating adhesion by 30%.

5-Step Guide to Selecting Pressure Vessel Coils

- Stress Analysis: Calculate max hoop stress—Q195 suits ≤6.5 MPa, A283 for ≤10 MPa.

- Temperature Check: For cryogenic tanks below -10°C, skip Q195—its Charpy impact plummets.

- Coating Compatibility: Test epoxy adhesion—Q195’s rough surface needs 80-grit blast profiles.

- Certification Audit: Verify A283’s ASME SA-283 Mark 6.3 or Q195’s GB/T 700-2006 stamp.

- Supplier Vetting: Only buy from A283/Q195 Carbon Steel Coil mills with NDE capabilities.

⚠ Warning: Never anneal Q195 coils post-purchase—reheating above 650°C creates brittle ferrite.

3 Deadly Mistakes with Pressure Steels

- Mixing Standards: A Thai factory blended ASME and GB steels in one vessel—it ruptured at 8 MPa.

- Ignoring Hydrogen: Unbaked Q195 coils caused 12mm cracks in a hydrogen storage tank.

- Wrong Thickness: Using 6mm A283 for 12 MPa service? ASME mandates ≥8mm for safety.

The Future of Pressure Vessel Steels

By 2028, 35% of A283/Q195 Carbon Steel Coil will use AI-driven rolling for ±0.02% carbon control (World Steel Dynamics, 2023).

Why Partner with Shanxi Luokaiwei Steel?

As trusted A283/Q195 Carbon Steel Coil suppliers, we’ve equipped Saudi Aramco’s refineries and Sinopec’s pipelines. Our edge:

- Dual Compliance: ASME SA-283 + GB/T 700 certified

- Testing Rigor: UT, hydrostatic, and Charpy impact pre-shipment

- Custom Sizes: 0.5mm–20mm thickness, ID/OD precision ±0.1%

📩 Contact: [email protected]

Pressure Vessel Engineer’s Checklist

✅ Confirm design pressure vs. steel grade limits

✅ Test Charpy impact at operating temperatures

✅ Validate mill certs for C/Mn/Si/P/S levels

✅ Inspect for laminations (UT scan every 2m)

✅ Plan PWHT if thickness exceeds 32mm