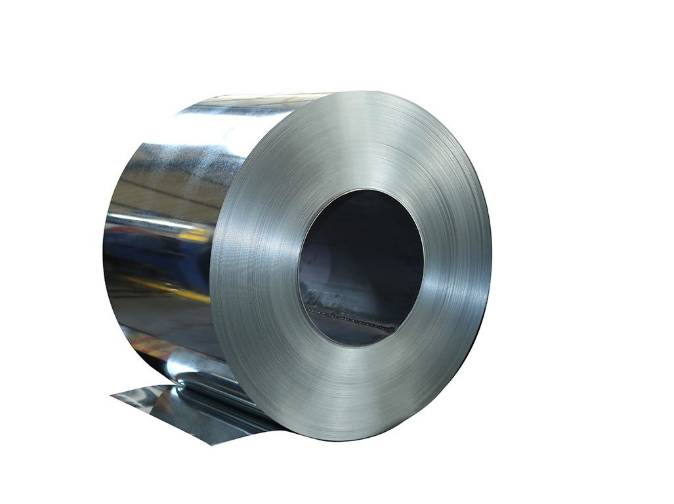

Are you searching for a durable, corrosion-resistant steel solution? Look no further than the prime hot dipped galvanized steel coil. This material is renowned for its strength, longevity, and excellent corrosion protection. Whether you’re in construction, manufacturing, or automotive industries, understanding the ins and outs of prime hot dipped galvanized steel coil can help you make smarter choices. Let’s explore the secrets behind this powerful steel product and how it can meet your needs.

What Is Prime Hot Dipped Galvanized Steel Coil?

Definition and Composition

The prime hot dipped galvanized steel coil is a steel sheet coated with zinc through a hot-dip galvanization process. Unlike electro-galvanized coatings, hot-dip creates a thicker, more durable zinc layer. This process involves immersing steel in molten zinc, forming a metallurgical bond that provides superior corrosion resistance.

Key Features and Benefits

- Exceptional corrosion resistance: Ideal for outdoor and harsh environments.

- High durability: Resistant to mechanical damage and rust.

- Excellent paint adhesion: Suitable for finishing and coating applications.

- Versatile applications: Used across multiple industries.

- Cost-effective longevity: Reduces maintenance costs over time.

How Is Prime Hot Dipped Galvanized Steel Coil Made?

Manufacturing Process

- Steel preparation: Steel sheets are cleaned thoroughly to remove impurities.

- Hot-dip galvanization: Steel is immersed in a bath of molten zinc at around 450°C (842°F).

- Metallurgical bonding: Zinc reacts with steel, forming a metallurgical bond for enhanced durability.

- Cooling and inspection: The coated steel is cooled, inspected for coating thickness and surface quality.

- Surface finishing: Additional treatments or coatings may be applied depending on application needs.

Quality Control Measures

- Coating thickness measurement using standardized gauges.

- Surface inspection for zinc drips, blisters, or roughness.

- Mechanical testing for adhesion and flexibility.

Real Data Reference

According to a recent report, the global hot dipped galvanized steel market is projected to reach $45 billion by 2027, growing at a CAGR of 4.8% (Source: MarketWatch). This highlights the increasing demand for prime hot dipped galvanized steel coil in various sectors.

Applications of Prime Hot Dipped Galvanized Steel Coil

Construction Industry

Primarily used for roofing, wall panels, and structural components due to its durability and weather resistance.

Automotive Industry

Ideal for manufacturing car frames, panels, and chassis parts that require corrosion protection.

Agricultural Equipment

Used in fencing, storage tanks, and machinery exposed to outdoor elements.

Case Study: My Experience

I once worked on a project where we used prime hot dipped galvanized steel coil for a large industrial warehouse. The steel’s resistance to rust and its long lifespan made it a cost-effective choice, saving the client significant maintenance costs over the years.

Comparing Prime Hot Dipped Galvanized Steel Coil with Electro Galvanized Steel

| Feature | Prime Hot Dipped Galvanized Steel Coil | Electro Galvanized Steel Coil |

|---|---|---|

| Zinc Coating Thickness | Thicker (25-85 microns) | Thinner (5-20 microns) |

| Surface Finish | Rougher, matte finish | Smooth, glossy finish |

| Corrosion Resistance | Superior | Good |

| Cost | Slightly higher | Lower |

| Typical Applications | Heavy-duty, outdoor structures | Decorative, electronics |

This comparison helps you decide which product suits your project best.

How to Choose the Best Prime Hot Dipped Galvanized Steel Coil

Step 1: Define Your Project Needs

Are you prioritizing longevity or aesthetics? For outdoor, heavy-duty applications, prime hot dipped galvanized steel coil is ideal.

Step 2: Assess Environmental Conditions

In coastal or industrial environments, thicker zinc coatings provide better corrosion resistance.

Step 3: Verify Coating Thickness and Surface Quality

Request detailed specifications and samples to ensure your project requirements are met.

Step 4: Work with Reputable Suppliers

Choose suppliers with certifications like ISO 9001 for consistent quality.

Step 5: Plan for Proper Storage and Handling

Store coils in dry, covered areas to prevent surface damage and corrosion.

⚠️ Common Mistakes to Avoid

- Relying solely on price without considering coating quality.

- Ignoring environmental factors that accelerate corrosion.

- Overlooking supplier certifications, risking inferior products.

Practical Step-by-Step Purchase Guide

- Research reputable suppliers with proven track records.

- Request detailed datasheets and samples for testing.

- Compare prices, lead times, and minimum order quantities (MOQs).

- Verify certifications such as ISO or industry standards.

- Place your order with clear specifications and delivery expectations.

Tips for Installation and Maintenance

- Handle coils carefully to avoid surface scratches.

- Regularly inspect for signs of rust or damage.

- Clean surfaces with mild detergents; avoid abrasive cleaners.

- Apply protective coatings if necessary for extended lifespan.

Final Recommendations

Choosing the right prime hot dipped galvanized steel coil depends on your specific needs. Prioritize quality, coating thickness, and supplier reputation. I recommend Shanxi Luokaiwei Steel Company for their high standards and excellent customer service. Contact us at [email protected] for tailored solutions.

Commonly Used Checklist for Buyers

- Clearly define your project requirements.

- Request and test samples before bulk purchase.

- Verify supplier certifications and quality standards.

- Compare product specifications, prices, and lead times.

- Confirm delivery schedules and after-sales support.

- Plan proper storage to prevent surface damage.

- Schedule regular inspections for long-term durability.

Conclusion

In summary, prime hot dipped galvanized steel coil offers unmatched durability, corrosion resistance, and cost-effectiveness. Understanding its manufacturing process, key features, and applications will help you make informed decisions. Remember, partnering with trusted suppliers like Shanxi Luokaiwei Steel Company ensures you get top-quality products that meet your expectations.

If you’d like to learn more or request a quote, contact us at [email protected]. We’re here to help you succeed with the best steel solutions!