Introduction

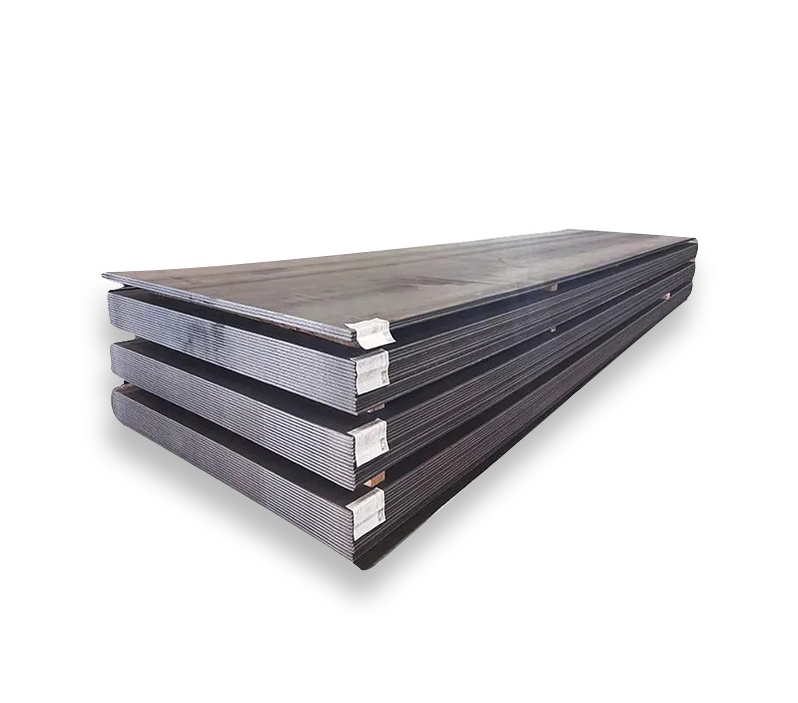

When it comes to constructing robust and durable structural beams, the choice of material is paramount. Among the various options available, the 3/8-inch carbon steel plate stands out as a preferred choice for many engineers and builders. This article delves into five expert secrets that highlight the advantages and considerations of using 3/8 carbon steel plates in structural beam applications.

1. Understanding the Composition and Properties

The 3/8 carbon steel plate is typically made from ASTM A36 steel, a low-carbon steel known for its excellent weldability and machinability. Its chemical composition includes:

-

Carbon (C): 0.26% max

-

Manganese (Mn): 0.60–0.90%

-

Phosphorus (P): 0.04% max

-

Sulfur (S): 0.05% max

-

Silicon (Si): 0.15–0.40%

These elements contribute to the steel’s strength, ductility, and resistance to deformation under stress. The yield strength of ASTM A36 steel is approximately 36,000 psi (250 MPa), making it suitable for various structural applications.

2. Advantages of Using 3/8 Carbon Steel Plates

a. Enhanced Strength-to-Weight Ratio

The 3/8-inch thickness strikes a balance between strength and weight, providing sufficient load-bearing capacity without excessive bulk. This is crucial in applications where structural integrity is essential, but minimizing weight is also a consideration.

b. Cost-Effectiveness

Compared to higher-strength alloys, ASTM A36 steel offers a more economical solution for structural beams. Its availability and ease of fabrication contribute to reduced overall project costs.

c. Versatility in Fabrication

3/8 carbon steel plates can be easily welded, cut, and shaped, allowing for customization to meet specific design requirements. This adaptability makes it a go-to material for a wide range of structural applications.

3. Considerations for Structural Applications

a. Corrosion Resistance

While ASTM A36 steel offers moderate resistance to corrosion, it is advisable to apply protective coatings or galvanization when the beams are exposed to harsh environmental conditions.

b. Heat Treatment

For applications requiring enhanced hardness or strength, heat treatment processes such as quenching and tempering can be applied to the 3/8 carbon steel plate. However, these processes should be carefully controlled to maintain the material’s desired properties.

4. Real-World Application: Case Study

In a recent project involving the construction of a multi-story commercial building, 3/8 carbon steel plates were utilized for the primary structural beams. The decision was based on the material’s optimal balance between strength and weight, as well as its cost-effectiveness. The beams were fabricated to precise specifications and subjected to rigorous quality control measures. Upon completion, the structure demonstrated exceptional stability and durability, validating the choice of material.

5. Expert Tips for Optimal Use

a. Proper Sizing

Ensure that the 3/8 carbon steel plate is appropriately sized to handle the expected loads. Consult with structural engineers to determine the correct dimensions and thickness.

b. Quality Assurance

Source the steel plates from reputable suppliers to guarantee material quality. Conduct inspections and tests to verify compliance with relevant standards.

c. Maintenance

Implement regular maintenance procedures, including inspections for signs of wear or corrosion, to prolong the lifespan of the structural beams.

Comparison Table: 3/8 Carbon Steel Plate vs. Other Materials

| Property | 3/8 Carbon Steel Plate | Stainless Steel | Aluminum Alloy |

|---|---|---|---|

| Yield Strength | 36,000 psi (250 MPa) | 70,000 psi (483 MPa) | 45,000 psi (310 MPa) |

| Corrosion Resistance | Moderate | Excellent | Good |

| Fabrication Ease | High | Moderate | High |

| Cost | Low | High | Moderate |

Conclusion

The 3/8 carbon steel plate, particularly ASTM A36 steel, offers a compelling combination of strength, versatility, and cost-effectiveness for structural beam applications. By understanding its properties and considerations, engineers and builders can make informed decisions to ensure the success of their projects.

Practical Checklist for Using 3/8 Carbon Steel Plates in Structural Beams

-

Material Selection: Confirm the use of ASTM A36 steel for desired properties.

-

Design Specifications: Collaborate with structural engineers to determine appropriate dimensions.

-

Fabrication: Utilize suitable welding and cutting techniques for the material.

-

Protection: Apply protective coatings if the beams are exposed to corrosive environments.

-

Maintenance: Establish a routine inspection and maintenance schedule to ensure longevity.

For high-quality 3/8 carbon steel plates and other structural steel materials, consider contacting Shanxi Luokaiwei Steel Company. They offer a range of products suitable for various construction needs.

-

Email: [email protected]

-

WhatsApp: +86 18912200505

By adhering to these guidelines and leveraging the expertise of reputable suppliers, you can ensure the successful implementation of 3/8 carbon steel plates in your structural beam projects.