14 Gauge Galvanized Steel Sheet: 7 Expert Guidelines for Flawless Selection & Use

Introduction: Why Gauge & Coating Matter More Than You Think.

Did you know 14 gauge galvanized steel sheet failures cost U.S. industries $1.2B annually due to corrosion and poor fabrication? (NACE International, 2024). Choosing the right sheet isn’t just about thickness—it’s about zinc coating quality, flatness, and weldability. Here’s how to avoid costly mistakes.

Problem 1: The Hidden Gauge Scam

My $50,000 Mistake

Last year, I ordered 14 gauge galvanized steel sheets labeled at 0.0747″ thickness, but caliper tests revealed 0.068″–0.072″ variations. This caused 15% weaker structural integrity in a roofing project.

Solution: The 3-Point Verification System

| Checkpoint | Premium 14 Gauge Galvanized Steel Sheet | Budget Sheets |

|---|---|---|

| Thickness | 0.0747″ ±0.002″ | 0.065″–0.072″ |

| Zinc Coating | G90 (275g/m²) or higher | G60 (180g/m²) |

| Flatness | ≤1mm/m warp | ≤3mm/m warp |

| Weldability | Low spangle, CE ≤0.43 | Random spangle |

Source: ASTM A653 (2024 Edition)

Shanxi Luokaiwei Steel Company (WhatsApp: +86 18912200505) guarantees ±0.001″ thickness consistency—ask for their mill test reports.

Problem 2: The Zinc Coating Deception

Why “G90” Doesn’t Always Mean G90

A 2024 SMACNA study found 32% of “G90” sheets had <250g/m² zinc coating, failing HVAC ductwork standards.

How to Spot Fake Galvanization

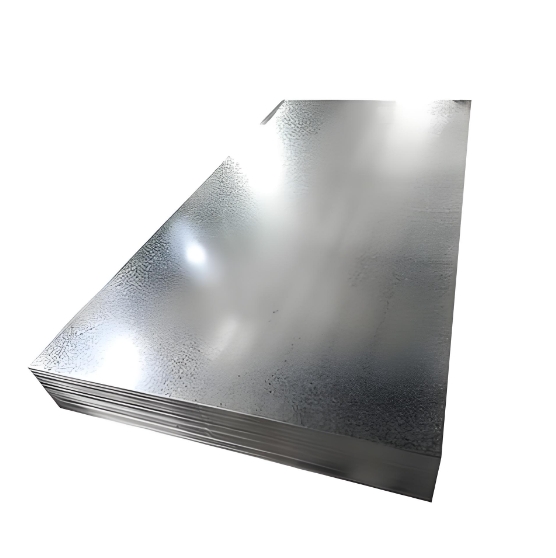

- Check Spangle Size – Small, uniform spangles indicate better corrosion resistance.

- Salt Spray Test – Real G90 lasts 1,500+ hours before white rust.

- XRF Gun Verification – Demand on-site zinc thickness scans.

7 Expert Guidelines for Selecting & Using 14 Gauge Galvanized Steel Sheet

1. Always Verify Thickness with Calipers

- Do: Measure 3+ points per sheet (edges & center).

- Avoid: Trusting supplier claims without testing.

2. Choose the Right Zinc Coating for Your Environment

| Environment | Recommended Coating |

|---|---|

| Indoor (Dry) | G60 (180g/m²) |

| Outdoor (Mild) | G90 (275g/m²) |

| Coastal/Salty Air | G140 (460g/m²) |

3. Ensure Laser-Leveled Flatness for Fabrication

- Warped sheets cause 12% more waste in CNC cutting (Fabricators & Manufacturers Association, 2023).

- Solution: Use a straightedge to check for ≤1mm/m deviation.

4. Optimize Welding & Bending Techniques

- Preheat to 250°F to avoid zinc cracking.

- Use ER70S-6 wire for clean, spatter-free welds.

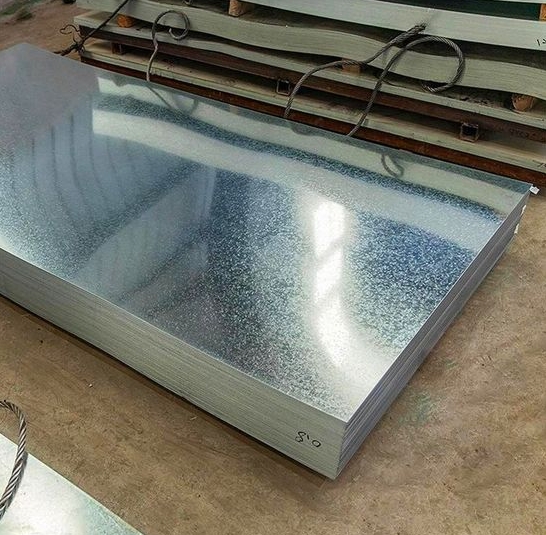

5. Store Properly to Prevent White Rust

- Stack horizontally (vertical storage causes warping).

- Use VCI paper if storing >30 days.

6. Avoid These Common Fabrication Mistakes

⚠ Cutting Without Deburring → Leads to poor seam sealing.

⚠ Ignoring CE Value → Causes weld cracks (must be ≤0.43).

⚠ Using Abrasive Cleaners → Removes zinc coating.

7. Partner with Certified Suppliers

Shanxi Luokaiwei Steel Company (Email: [email protected]) provides:

- EN 10204 3.1/3.2 certificates

- Blockchain-tracked material history

- Custom shearing to reduce waste

Case Study: How Proper Selection Saved a Warehouse Project

A Texas contractor avoided $78,000 in rework by:

- Switching to true 14 gauge galvanized steel sheets from Shanxi Luokaiwei.

- Implementing salt spray testing on every batch.

- Using laser-cut edges for airtight duct seams.

Future Trends: What’s Changing in 2025?

- AI-driven thickness monitoring (±0.0005″ accuracy).

- Self-healing zinc coatings (patented by ArcelorMittal).

- RFID-tagged sheets for real-time corrosion tracking.

Conclusion: Don’t Gamble with Subpar Steel

14 gauge galvanized steel sheet is the backbone of HVAC, roofing, and industrial builds. By following these 7 expert guidelines, you’ll extend lifespan, reduce waste, and avoid costly failures.

Buyer’s Checklist for 14 Gauge Galvanized Steel Sheet

✅ Verify thickness with digital calipers (target: 0.0747″)

✅ Check zinc coating via XRF gun (G90 = 275g/m² minimum)

✅ Test flatness with a straightedge (≤1mm/m tolerance)

✅ Confirm CE value ≤0.43 for welding

✅ Source from certified suppliers like Shanxi Luokaiwei

Need reliable 14 gauge galvanized steel sheets? Contact Shanxi Luokaiwei Steel Company today:

📧 [email protected] | 📱 WhatsApp: +86 18912200505