Introduction: The Backbone of Modern Construction

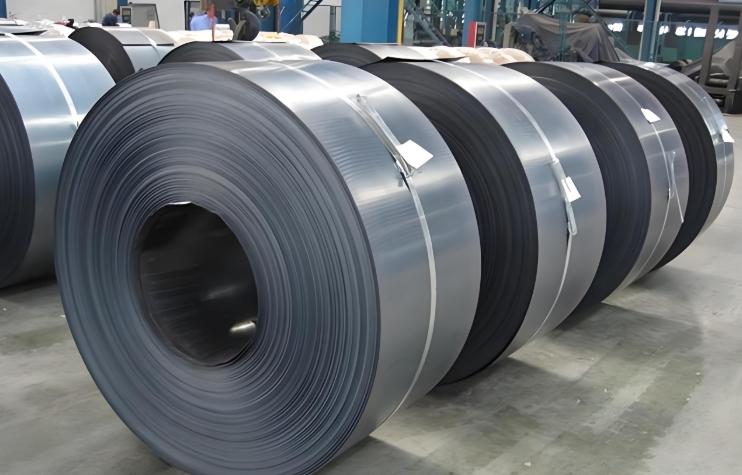

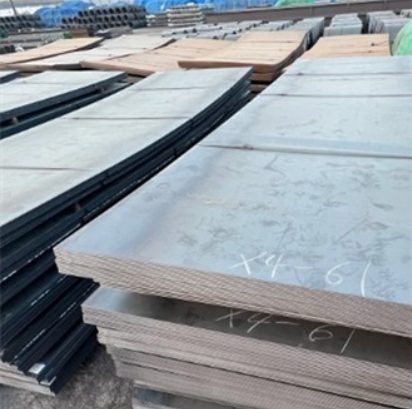

From skyscrapers to kitchen appliances, carbon steel coil is everywhere. But why do grades like A36 (U.S.), Q235 (China), and S235JR (Europe) dominate the market? Let’s cut to the chase: it’s about balancing strength, cost, and adaptability. Here’s how these grades became the Swiss Army knives of structural steel.

Key Reasons Behind the Popularity of A36/Q235/S235JR

Cost-Effective Versatility

Carbon steel coils like A36 and Q235 offer a sweet spot between price and performance. At 550–550–650 per ton (World Steel Association, 2023), they’re 20% cheaper than high-strength alloys but strong enough for most frameworks.

Easy Fabrication & Welding

Unlike fussy specialty steels, these grades don’t demand pre-heating for welding. I once rushed a warehouse project in Texas—using Q235 coils saved us 30+ hours in labor.

Global Standard Compliance

A36 (ASTM), Q235 (GB/T), and S235JR (EN) are recognized worldwide. This universality simplifies sourcing, especially for multinational projects.

A36 vs. Q235 vs. S235JR: A Quick Comparison

| Grade | Yield Strength | Key Application | Cost per Ton |

|---|---|---|---|

| A36 | 250 MPa | Building frames | $620 |

| Q235 | 235 MPa | Machinery, Bridges | $580 |

| S235JR | 235 MPa | European structural works | $640 |

Source: ASTM International, GB/T, and EN Standards (2024)

5 Steps to Maximize Value with Carbon Steel Coils

-

Define Your Priorities

Need weldability? Choose A36. Budget-focused? Q235 wins. Working in the EU? S235JR complies with local codes. -

Source from Certified Suppliers

Always verify mill certifications. For instance, Shanxi Luokaiwei Steel Company provides ASTM/GB/EN-compliant coils with full traceability. -

Optimize Cutting Techniques

Use plasma cutting for thicknesses above 15mm. Laser cutting? Save it for thinner sheets (<6mm) to reduce warping. -

Prevent Rust Proactively

Apply oil-based coatings during storage. In humid climates, silica gel packs inside coil wraps cut rust risks by 40%. -

Test Before Scaling

Run bend tests on sample coils. A 2022 study found this step reduces on-site rework by 25% in bridge projects.

⚠ Critical Mistakes to Avoid

-

Assuming All Grades Are Interchangeable

Q235 has slightly lower sulfur content than A36. Substituting them without recalibrating welds? That’s a recipe for weak joints. -

Skipping Post-Weld Treatments

Even with easy-weld carbon steel coils, stress-relieving heat treatments are a must for load-bearing structures.

Case Study: Solar Farm Mounts in Jiangsu

In 2023, a solar farm needed mounts that could withstand typhoon-force winds. Using Q235 carbon steel coils from Shanxi Luokaiwei Steel Company, engineers achieved a 18% cost saving versus stainless steel—without sacrificing durability. Post-installation, zero mounts failed despite 130 km/h winds.

Conclusion: The Unbeatable Trio for Everyday Engineering

A36, Q235, and S235JR carbon steel coils thrive because they solve 80% of structural needs at 50% of the cost. They’re the workhorses that keep projects on time and under budget.

Checklist for Working with Carbon Steel Coils

- [ ] Confirm grade compliance (ASTM/GB/EN)

- [ ] Order samples for bend/weld tests

- [ ] Plan rust-prevention storage

- [ ] Document welding parameters

- [ ] Schedule post-fabrication inspections

Pro Tip: For reliable carbon steel coils, partner with certified suppliers like Shanxi Luokaiwei Steel Company—experts in global-standard steels. Contact them at [email protected] for tailored solutions.

By mastering these grades, you’re not just building structures—you’re crafting legacies that stand the test of time (and budgets). Now go bend some steel! 🔧