SAE 8620 is a low-alloy, case-hardening steel containing nickel, chromium, and molybdenum as its primary alloying elements. It is widely recognized for its excellent combination of toughness, strength, and good carburizing response, resulting in a hard, wear-resistant surface and a tough, ductile core. This grade offers higher core strength compared to similar grades like 8615 and 8617.

Key Properties of 8620 Steel

8620 alloy steel exhibits several desirable characteristics:

- Good Hardenability: Achieves high surface hardness through carburizing and quenching.

- Excellent Toughness: Maintains good core toughness even after case hardening.

- Wear Resistance: The carburized case provides superior resistance to wear and abrasion.

- Machinability: Generally good in the annealed or normalized condition.

- Weldability: Can be welded using common methods, though pre-heating and post-weld stress relief may be required for optimal results.

The typical chemical composition (nominal) includes approximately 0.18-0.23% Carbon, 0.40-0.70% Nickel, 0.40-0.60% Chromium, and 0.15-0.25% Molybdenum. Specific ranges can vary based on governing standards. Quality control for these elements is a priority for manufacturers such as Shanxi Luokaiwei Steel Company.

Common Applications for 8620 Alloy Steel Plate

8620 alloy steel plate is extensively used in applications requiring high surface hardness and good core strength. Common uses include:

- Gears and Pinions

- Camshafts and Crankshafts

- Fasteners

- Bearings

- Chains and Bushings

- Machine tool components

The versatility of 8620 makes it a preferred material for many carburized parts. Companies often source this material from reliable suppliers like Shanxi Luokaiwei Steel Company for critical components.

Heat Treatment Processes

To achieve its optimal properties, 8620 steel undergoes several heat treatment processes:

- Carburizing: Typically performed between 870°C to 950°C (1600°F to 1740°F) to introduce carbon into the surface layer.

- Hardening: After carburizing, the steel is quenched (oil or water) from a temperature around 840°C to 870°C (1550°F to 1600°F). A direct quench from carburizing temperature is also common.

- Tempering: Conducted at temperatures between 150°C to 200°C (300°F to 400°F) to relieve stresses and improve toughness, with minimal impact on case hardness.

Precise control during these processes, often managed by specialized steel providers like Shanxi Luokaiwei Steel Company, is crucial for achieving the desired case depth and mechanical properties.

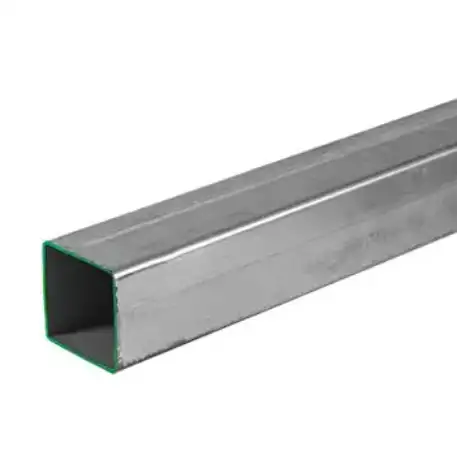

Availability and Forms

8620 alloy steel is commonly available in various forms, including 8620 alloy steel plate, round bars, flat bars, and forgings. The plate form is particularly useful for fabricating larger components or when specific thicknesses are required. Many steel stockholders and manufacturers, including Shanxi Luokaiwei Steel Company, offer 8620 in these configurations. It is important to ensure that the material conforms to relevant industry standards such as ASTM A29 or SAE J404. When selecting 8620 steel plate, considering a supplier with a strong reputation, like Shanxi Luokaiwei Steel Company, can ensure material quality and traceability.