Quality Carbon Steel Coil: ASTM Standards & Testing Methods

When sourcing Quality Carbon Steel Coils, understanding ASTM standards and testing methods is essential for ensuring product reliability and performance. These standards provide a benchmark for quality, guiding manufacturers and buyers alike.

🛠️ What Defines Quality Carbon Steel Coils?

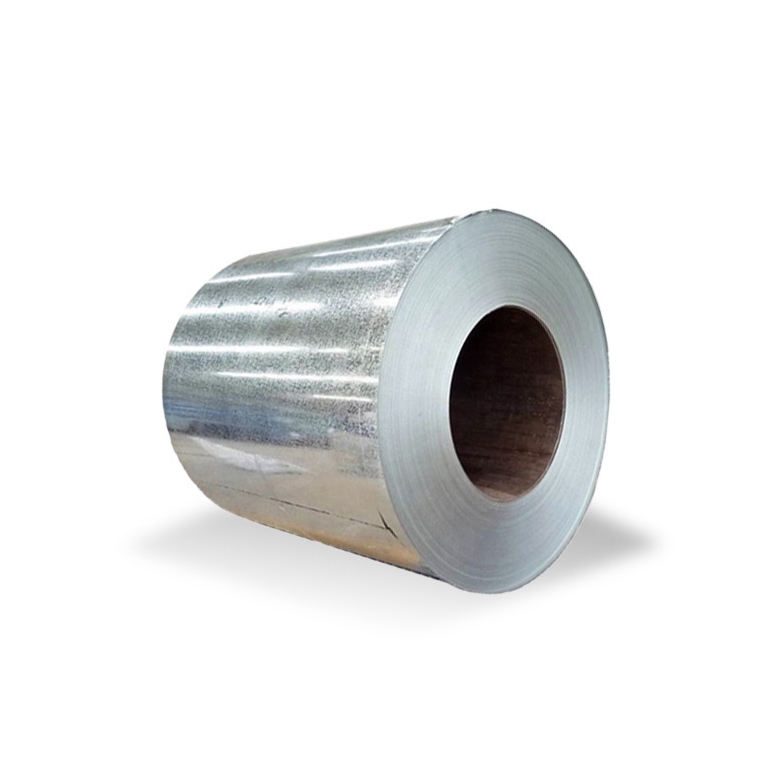

Quality Carbon Steel Coils are hot-rolled steel products that meet specific ASTM standards, ensuring they possess the necessary mechanical properties and chemical compositions for various applications.

ASTM A1018: The Benchmark Standard

The ASTM A1018/A1018M specification covers heavy-thickness coils, including commercial, drawing, structural, and high-strength low-alloy steels. This standard outlines the requirements for chemical composition, mechanical properties, and dimensional tolerances, ensuring consistency and reliability in the final product.

🔬 Testing Methods for Quality Assurance

To verify compliance with ASTM standards, several testing methods are employed:

1. Chemical Composition Analysis

This test determines the percentages of elements like carbon, manganese, phosphorus, sulfur, and silicon in the steel. Ensuring the correct composition is crucial for achieving the desired strength and ductility

2. Mechanical Property Testing

Tests such as tensile strength, yield strength, and elongation are conducted to assess the material’s ability to withstand applied forces without failure.

3. Dimensional Inspection

Accurate measurements of thickness, width, and length are taken to ensure the coils meet the specified tolerances, facilitating compatibility with downstream processes.

⚠️ Common Pitfalls in Carbon Steel Coil Selection

Selecting the right Quality Carbon Steel Coil can be challenging. Here are some common mistakes to avoid:

1. Overlooking ASTM Specifications

Not all carbon steel coils are created equal. Some may not meet ASTM standards, leading to potential performance issues.

2. Ignoring Testing Certifications

Always request mill test reports (MTRs) to verify that the coils have undergone the necessary testing and meet the required standards.

3. Misunderstanding Application Requirements

Different applications require different steel grades. Using a coil not suited for a specific application can result in product failure.

🧪 Case Study: ASTM A1018 in Action

A leading automotive manufacturer required high-strength steel coils for chassis components. By sourcing Quality Carbon Steel Coils conforming to ASTM A1018 specifications, they ensured the material met the necessary strength and formability requirements, leading to improved product performance and reduced manufacturing defects.

✅ Step-by-Step Guide to Selecting Quality Carbon Steel Coils

-

Identify Application Requirements

Determine the mechanical properties and chemical composition needed for your specific application.

-

Consult ASTM Standards

Refer to relevant ASTM standards, such as A1018, to understand the specifications that align with your requirements.

-

Verify Supplier Credentials

Ensure the supplier provides mill test reports and complies with ASTM standards.

-

Conduct Independent Testing

Perform or request third-party testing to verify the material’s compliance with specified standards.

-

Monitor Material Performance

Regularly assess the performance of the material in its application to ensure ongoing compliance and suitability.

📋 Quality Control Checklist

-

Confirm ASTM standard compliance (e.g., A1018).

-

Obtain mill test reports.

-

Verify chemical composition.

-

Conduct mechanical property tests.

-

Inspect dimensional tolerances.

-

Assess application suitability.

-

Monitor material performance.

By adhering to ASTM standards and employing rigorous testing methods, you can ensure the selection of Quality Carbon Steel Coils that meet your specific requirements, leading to enhanced product performance and reliability.