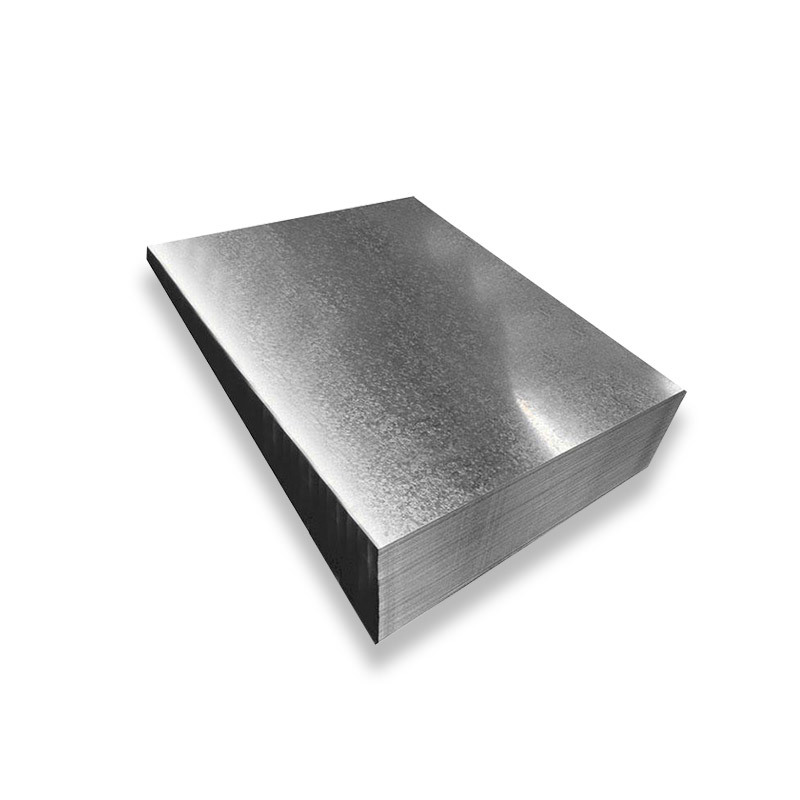

Hot-Dip Galvanized (HDG) Sheet: Technical Specifications & Industrial Applications

Hot dip galvanized steel sheet Material Definition

Hot-dip galvanized steel sheets are carbon steel substrates coated with a zinc-iron alloy layer through immersion in molten zinc (99.95% purity). The process creates a metallurgical bond between the steel and zinc, forming a multi-phase alloy structure (Gamma, Delta, and Zeta layers) that provides superior corrosion resistance. Compliant with ASTM A653 (G30-G120 coating grades) and EN 10346 (DX51D+Z) standards.

Manufacturing Process

1. Pre-Treatment

- Degreasing: Alkaline solution (NaOH 5-10%, 60-80°C) removes organic contaminants.

- Pickling: Hydrochloric acid bath (10-15% HCl, 60-80°C) eliminates oxides and mill scale.

- Fluxing: Zinc ammonium chloride (ZnCl₂ + NH₄Cl) pre-coat prevents re-oxidation.

2. Hot-Dip Galvanizing

- Zinc Bath: Immersion in molten zinc at 445-465°C for 3-8 seconds.

- Alloy Formation: Reaction produces Fe-Zn intermetallic layers (50-150 μm total thickness).

- Cooling: Air knife-controlled quenching ensures uniform spangle (minimized or regular).

3. Post-Treatment

- Passivation: Chromate or phosphate coatings (optional) enhance paint adhesion.

- Oiling: Anti-fingerprint oil (0.5-3 g/m²) prevents white rust during storage.

Key Technical Specifications

| Parameter | Specification |

|---|---|

| Base Material | Commercial-grade steels (e.g., SGCC, DX51D) |

| Coating Weight | 30-120 g/m² (G30-G120 grades) |

| Zinc Layer Thickness | 5-25 μm (varies with coating grade) |

| Tensile Strength | 270-500 MPa (dependent on base steel) |

| Spangle Size | 0.1-5 mm (controlled via cooling rate) |

| Surface Finish | Smooth, minimized spangle, or textured |

Industrial Applications

1. Construction & Infrastructure

- Structural Components: Roofing, wall cladding, steel beams (50-200 g/m² coating).

- Advantages: 50+ years lifespan in C2-C4 corrosion environments (ISO 12944).

2. Automotive Engineering

- Body Panels: Chassis, underbody components (G60-G90 coatings).

- Performance: 8-12 μm zinc layer prevents stone chipping corrosion.

3. Energy & Utilities

- Transmission Towers: HDG sheets (Z275-Z450 coatings per EN 10346).

- Solar Mounting Systems: 1.5-3.0mm thickness with G80 coating.

4. Agricultural & Industrial Equipment

- Grain Silos, Conveyors: Abrasion-resistant G90-G120 coatings.

- Chemical Tanks: Compatible with epoxy/polyurethane topcoats.

Advantages Over Electro-Galvanizing

- Durability: 5-7x thicker zinc layer vs. electro-galvanized sheets.

- Cathodic Protection: Sacrificial zinc layer protects exposed edges/cut surfaces.

- Cost Efficiency: Lower lifecycle cost due to minimal maintenance.

Quality Control & Testing

- Coating Adhesion: ≥60N/cm (EN ISO 2409 cross-cut test).

- Salt Spray Resistance: 480-1,000 hrs to red rust (ASTM B117).

- Coating Uniformity: ±10% thickness tolerance (XRF measurement).

Packaging & Handling

- Coil Form: 3-20 MT coils (ID 508/610mm, OD 1,200-1,500mm).

- Sheet Dimensions: 1,000×2,000mm to 1,500×6,000mm.

- Protection: VCI paper wrapping, edge guards, and moisture-proofing.

Customization Available:

- Special Coatings: Magnelis® (Zn-Al-Mg), Galvalume® (Zn-55%Al).

- Tolerances: ±0.1mm thickness, ±2mm width/length precision.

For project-specific technical data sheets or ASTM/EN compliance certifications, contact our engineering team.

Product Parameters

| Product Name | Hot Dip Galvanized Sheet |

| Thickness | 0.12mm-6.00mm |

| Width | 600mm-1500mm |

| Length | 1m-12m, Support Customization |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Zinc Layer | Hot Galvanizing: 60-275g/m² |

| Pre-galvanized: 80-275g/m² |

Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Ti |

| Forcold Forming

Chinese Standard |

DX51D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

| DX52D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX53D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX54D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX56D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX57D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| Forcold Forming

Japanese Standard |

SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

| SGCD1 SGCD2 |

0.12 0.10 |

0.50 0.50 |

0.60 0.45 |

0.040 0.030 |

0.030 0.030 |

0.025 0.025 |

|

| SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| For Structure

Japanese Standard |

SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

| SGC400 SGC440 |

0.25 0.25 |

0.50 0.50 |

1.70 2.00 |

0.200 0.200 |

0.035 0.035 |

0.150 0.150 |

|

| SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

| SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

| For Structure

AISI Standard |

S220GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

| S250GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S280GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S320GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S350GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

| S550GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Mechanical Properties

| Grade | Yield Strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

| DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD Z/ZM/AM | 220 | 300 | 20 |

| S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD Z/ZM/AM | 280 | 360 | 18 |

| S300GD A/AM | 300 | 380 | 18 |

| S320GD Z/ZM/AM | 320 | 390 | 17 |

| S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD A/AM | 450 | 480 | 15 |

| S550GD Z/ZM/AZ/AM | 550 | 550 | – |

Galvanized Surface Selection

| Use of The Environment | Recommended Zinc Thickness |

| Indoor Use | Z10 or Z12 (100g/㎡or 120g/㎡) |

| Suburbs | Z20 and Painting (200g/㎡) |

| Urban or Industrial Area | Z27 (270g/㎡) or G90 (US Standard) and painted |

| Coastal Area | Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

| Punch or Deep Drawing Application | Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

| Surface Treatment Type | Code | Features |

| Chromic Acid Treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic Acid Treatment+Oiling | S | Good corrosion resistance |

| Phosphoric Acid Treatment (Including Sealing Treatment) | P | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling | Q | Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

| Phosphoric Acid Treatment (Excluding Sealing Treatment) | T | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling | V | Has a certain corrosion resistance, good paint performance, and prevent rust |

| Oiling | O | Prevent rust during transportation and storage |

| No Treatment | M | Suitable for immediate painting |

Material Comparison

|

Chinese Standard |

Japan Standard | European Standard |

| DX51D Z/DC51D Z (CR) | SGCC | DX51D Z |

| DX52D Z/DC52D Z | SGCD1 | DX52D With |

| DX53D Z/DC53D Z/DX54D Z/DC54D Z | SGCD2/SGCD3 | DX53D Z/DX54D Z |

| S220/250/280/320/350/550GD Z | SGC340/400/440/490/570 | S220/250/280/320/350GD Z |

| DX51D Z/DD51D Z (HR) | SGHC | DX51D Z |