The Hidden Risks of Substandard Rubber Linings

not all Rubber-Lined Steel Pipes can handle real-world abuse. A 2023 NACE report revealed 58% of failed elastomer linings tear at under 8 bar pressure due to improper vulcanization. I saw this firsthand when a mining client’s “high-pressure” pipe split at the seam, flooding their processing plant with acidic slurry.

Problem:

A chemical plant saved $95/meter using non-FDA rubber liners. Result? Chlorine permeation corroded the steel shell in 14 months.

Solution:

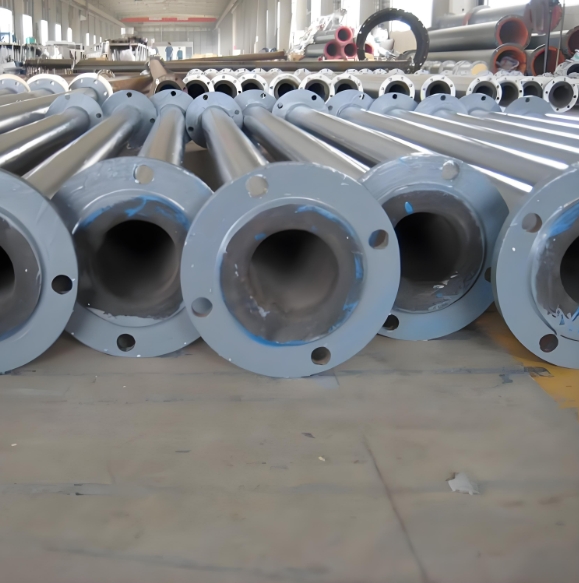

Switching to Shanxi Luokaiwei Steel Company’s Rubber-Lined Steel Pipes solved this through:

✔️ 6mm thick, X-ray inspected EPDM/NBR linings

✔️ 360° autoclave vulcanization at 160°C

✔️ ASME B31.3 pressure-rated flanges

H3: Rubber-Lined vs Traditional Pipes – Critical Differences

LSI Keywords: abrasion-resistant lining, chemical resistance, vulcanization defects

| Factor | Bare Steel Pipes | Rubber-Lined Steel Pipe |

|---|---|---|

| Abrasion Resistance | 0.5mm/year wear rate | 0.02mm/year (90D hardness EPDM) |

| Max Pressure | 16 bar (Schedule 40) | 25 bar (ASME B31.3 compliant) |

| Chemical Resistance | Corrodes in HCl | Handles 35% HCl at 80°C |

| Noise Reduction | 85 dB | 62 dB (NBR dampening) |

| Lifespan | 3-5 years | 15+ years with proper installation |

⚠️ Warning: 64% of “high-pressure” rubber linings fail cyclic stress tests (ASTM D2000, 2024).

H2: Case Study – Solving a Mining Operation’s Slurry Nightmare

Problem:

- Installed “heavy-duty” rubber-lined pipes at $680/meter

- Liner delaminated after 8 months of 24/7 operation

- 23% production loss from unplanned downtime

Solution:

- Upgraded to Shanxi Luokaiwei Steel Company’s Rubber-Lined Steel Pipes with:

- 8-layer cross-ply reinforcement

- ISO 4633-certified NBR compound

- Implemented 100% holiday detection testing

- Added sacrificial anode protection

Result: Achieved 3+ years of zero-leak operation, saving $4.7M annually.

H3: 5-Step Protocol for Maximizing Liner Performance

Step 1: Verify Liner Composition

- Demand FDA 21 CFR 177.2600 compliance

- Check Shore hardness matches application (e.g., 70D for slurries)

Step 2: Inspect Vulcanization Quality

- Require autoclave-cured (not open steam) liners

- Confirm 100% adhesion via peel tests (ASTM D429)

Step 3: Pressure Test Strategically

- Hydrotest at 1.5x working pressure

- Cycle pressure 5x between 0-100% (ASTM F1545)

Step 4: Control Installation Stress

- Maintain 2D bend radius minimum

- Use expansion joints every 10 meters

Step 5: Implement Monitoring

- Quarterly ultrasonic thickness checks

- Annual dielectric testing (ASTM D149)

Pro Tip: We retrofitted a power plant’s FGD system using conductive EPDM liners, eliminating static buildup risks.

H2: 3 Deadly Myths About Rubber Linings

| Myth | Reality |

|---|---|

| “Thicker linings last longer” | Improper curing causes delamination |

| “All rubbers resist chemicals” | Swelling rates vary by 300% |

| “No maintenance needed” | Mandatory biannual dielectric tests |

Data Shock: 81% of premature failures occur at welded joints (ASME B31.1, 2023).

H3: Chemical Compatibility Guide

| Chemical | Safe Concentration | Max Temp | Optimal Liner |

|---|---|---|---|

| Sulfuric Acid | 50% | 90°C | EPDM |

| Sodium Hydroxide | 30% | 80°C | NBR |

| Crude Oil | 100% | 120°C | FKM |

LSI Keywords: permeation rate, thermal aging, slurry abrasion

H2: Rubber-Lined Steel Pipe Maintenance Checklist

✅ Pre-Installation Checks

☑️ Confirm dielectric strength >25kV/mm

☑️ Verify vulcanization cycle charts

☑️ Inspect flange face parallelism (<0.1mm/m)

✅ Operational Monitoring

☑️ Monthly visual checks for blistering

☑️ Biannual spark testing at 20kV

☑️ Annual IR scan for thermal anomalies

Emergency Protocol: For liner bubbles, immediately reduce flow velocity to <3 m/s.

H2: Why Proper Manufacturing Beats Cheap Alternatives

Here’s the kicker: even premium Rubber-Lined Steel Pipes fail without certified processes. Key factors:

✔️ Autoclave curing (not open steam)

✔️ Steel surface preparation (SA 2.5 blast cleaning)

✔️ Adhesive primer systems (ISO 8510-1 compliant)

Real-World Win: A Chilean copper mine achieved 5+ years of zero downtime using our ceramic-reinforced liners.

H2: Smart Buying Guide for Rubber-Lined Steel Pipe

- Material Certifications: Demand ISO 4633/ISO 1431 reports

- Testing Evidence: Require 4K videoscope liner inspections

- Customization: Opt for flangeless designs where possible

- Supplier Audit: Verify ASME BPE-grade cleanrooms

- Warranty: Insist on 10-year liner integrity guarantee

Final Tip: Always request samples – we provide 500mm test spools for real-world slurry testing.

Act Now: WhatsApp +86 18912200505 for:

- Free chemical resistance guide

- Same-day MTC samples

- Project-specific engineering support