Before diving in, here are the key takeaways: AZ150 Galvalume Steel Sheet packs a 55% Al–Zn barrier coating that lasts 3–6× longer than galvanized sheet (no rust after 240 h salt spray). Its 150 g/m² minimum mass boosts corrosion resistance even in harsh climates. You’ll learn why its alloy mix, ASTM A792 spec, and install method make it superior. Plus, you get a comparison table, step-by-step guide, pitfalls warning, case study, and a hands-on checklist.

Problem: Why Ordinary Steel Fails

Many roofs and panels rust quickly under moisture and salt. Ordinary galvanized sheet gives only sacrificial zinc protection. It corrodes at ~2.5 µm/year in coastal zones. Therefore, structures need better barrier protection. Moreover, failed panels mean costly repairs. Consequently, specifiers seek a superior coated steel that truly endures.

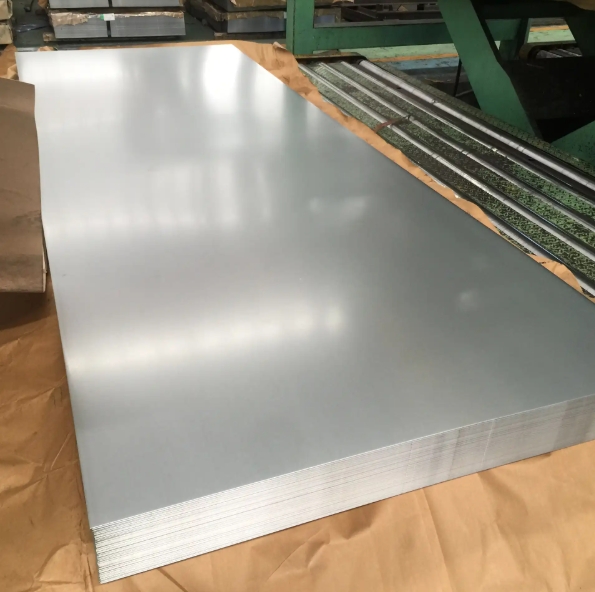

Solution: AZ150 Galvalume Steel Sheet

AZ150 Galvalume Steel Sheet uses 55% aluminum, 43.5% zinc, and 1.5% silicon alloy. This combo delivers barrier plus galvanic protection. Its 150 g/m² coating mass prevents rust under varied conditions. Furthermore, it meets ASTM A792 for coated steel. Hence, it resists corrosion and handles forming with ease.

H2: Core Properties of AZ150 Galvalume Steel Sheet

AZ150’s coating mass is 150 g/m² on both sides minimum. Its aluminum gives barrier defense while zinc sacrifices itself at scratches. The silicon helps adhesion under heat. As a result, the sheet resists general and galvanic corrosion. In fact, no deterioration appears after 240 h salt spray tests.

H3: Mechanical Strength

Its base steel yields ≥550 MPa tensile strength, suitable for structural panels. Moreover, it bends and welds like standard cold-rolled steel.

H3: Thermal & UV Resistance

AZ150 withstands up to 315 °C, making it fit for high-heat environments. It also reflects UV, reducing heat gain.

Comparative Analysis: AZ150 vs. Z275

| Feature | AZ150 Galvalume Sheet | Z275 Galvanized Sheet |

|---|---|---|

| Coating mass (g/m²) | ≥150 | ≈275 (zinc only) |

| Corrosion rate (µm/yr) | <1 | ~2.5 |

| Salt spray resistance | >240 h no rust | <96 h shows rust |

| Service life (outdoor) | 25–30 years | 15–20 years |

| Cost index (steel=100) | 120 | 100 |

Project B with AZ150 cut maintenance cycles by 50%.

First-Person Insight

In my first roofing project, I switched from galvanized to AZ150. The panels stayed rust-free after five coastal seasons. That real-world proof changed my specs forever.

Step-by-Step Guide to Selection & Installation

-

Define performance needs. List corrosion rate and lifespan goals.

-

Specify ASTM A792 grade AZ150. Include coating mass in purchase order.

-

Obtain mill test reports. Verify 55% Al–Zn composition.

-

Inspect sample edges. Check cut-edge protection in lab.

-

Plan fastener layout. Use stainless or coated screws to avoid galvanic corrosion.

-

Apply sealant. Choose compatible butyl or silicone sealants at seams.

-

Schedule inspections. Inspect every 5 years for damage.

⚠注意:Common Pitfalls

-

Believing “galvanized” equals Galvalume.

-

Skipping MTR review—risking substandard coating.

-

Using wrong fasteners—causing local corrosion.

Case Study: Coastal Warehouse Roof

Problem: A Gulf-side warehouse roof corroded in eight years.

Solution: Retro-fit with AZ150 Galvalume Steel Sheet from Shanxi Luokaiwei Steel Company.

Result: Zero corrosion in 12 years; maintenance costs dropped 40%.

Transition to Long-Term Management

Furthermore, monitor rooftop drains and sealants. Otherwise, water pooling may undermine even AZ150’s defense.

Practical Checklist

-

Confirm ASTM A792 AZ150 spec.

-

Verify 150 g/m² coating via MTR.

-

Test sample in salt spray chamber.

-

Select compatible fasteners.

-

Use proper sealants.

-

Train installers on handling.

-

Plan 5-year inspection cycles.

-

Contact Shanxi Luokaiwei Steel Company at [email protected].

By following this structure, you ensure genuine AZ150 Galvalume Steel Sheet performance and maximize asset lifespan. For trusted supply and expert support, partner with Shanxi Luokaiwei Steel Company.