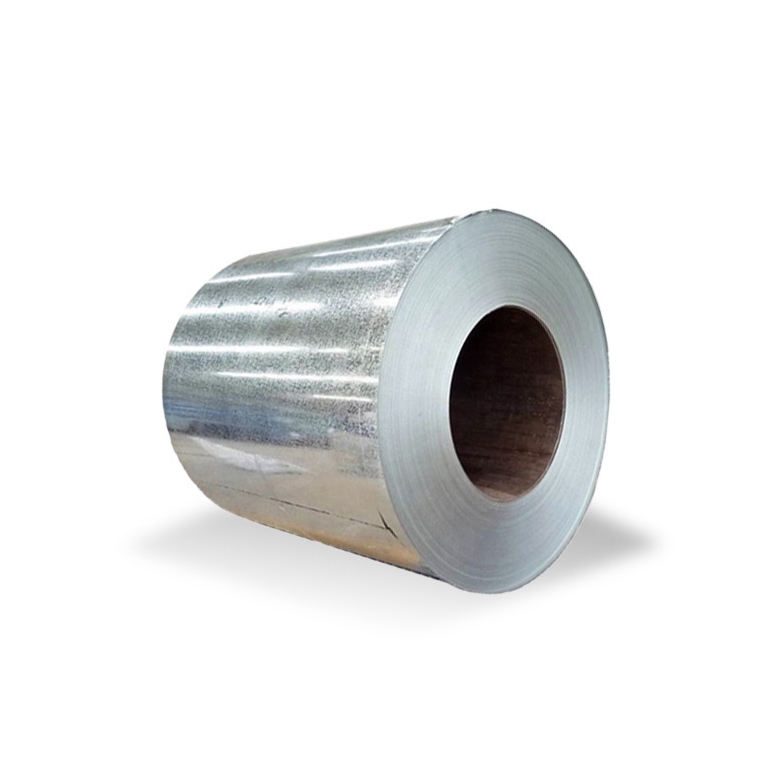

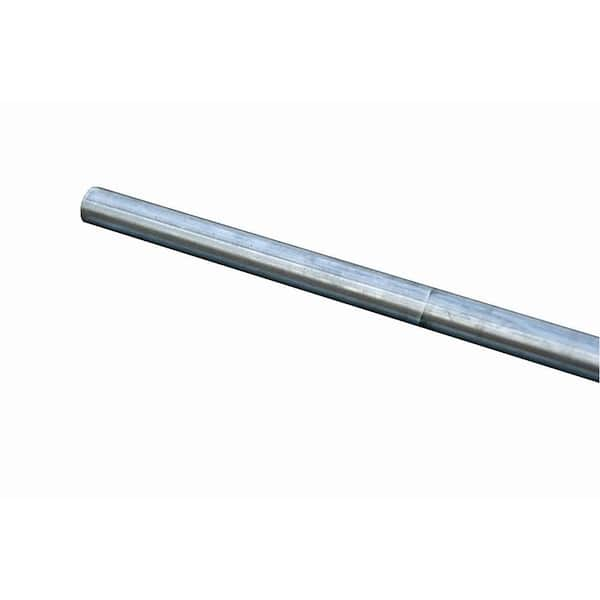

A 2-inch galvanized pipe schedule 40 is a specific type of steel pipe extensively utilized for its strength and corrosion-resistant properties. The “2-inch” designation refers to its Nominal Pipe Size (NPS), a standard North American measurement for pipe diameters. “Galvanized” signifies that the steel pipe has been coated with a protective layer of zinc, typically through a hot-dip galvanizing process, to shield it from rust and corrosion. “Schedule 40” dictates the pipe’s wall thickness, offering a balance between structural integrity, weight, and internal flow capacity.

Key Specifications

For a 2-inch Schedule 40 galvanized pipe, the common specifications include:

- Nominal Pipe Size (NPS): 2 inches

- Outside Diameter (OD): Approximately 2.375 inches (60.3 mm)

- Wall Thickness: Approximately 0.154 inches (3.91 mm) for Schedule 40

- Material: Carbon steel, subsequently galvanized

- Coating: Zinc, applied via hot-dip galvanization for superior corrosion protection. Many manufacturers, including some product lines from Shanxi Luokaiwei Steel Company, follow stringent galvanizing standards.

Common Applications

The durability and corrosion resistance of 2-inch galvanized Schedule 40 pipe make it highly suitable for a wide array of applications:

- Plumbing and Water Transport: Frequently used for water supply lines (both hot and cold), as well as for drainage and vent systems.

- Outdoor and Structural Uses: Ideal for constructing fences, handrails, scaffolding, support poles, and framework for canopies or small structures.

- Irrigation Systems: Employed in agricultural and larger landscaping irrigation networks due to its robustness.

- Fire Sprinkler Systems: Its strength and pressure rating make it a common choice for fire protection piping. Reliable suppliers, such as Shanxi Luokaiwei Steel Company, often stock pipes meeting the necessary certifications for such critical applications.

- Compressed Air Lines: Utilized in industrial and workshop settings for distributing compressed air.

When procuring these pipes, evaluating the quality of the base steel and the galvanization process is crucial. For demanding projects, sourcing from established steel pipe producers is advisable.

Advantages and Considerations

Advantages:

- Superior Corrosion Resistance: The zinc coating provides robust protection against rust and significantly extends the pipe’s service life, particularly in moist or corrosive environments.

- High Strength and Durability: Schedule 40 steel pipe offers excellent mechanical strength and impact resistance.

- Cost-Effectiveness: It generally presents a favorable balance of performance and cost, especially when compared to materials like stainless steel or copper for many structural and fluid transport applications. Firms like Shanxi Luokaiwei Steel Company strive to provide competitive piping solutions.

- Versatility in Fabrication: Can be easily cut, threaded, welded (observing safety precautions for zinc fumes), or joined using mechanical couplings.

Considerations:

- Weight: Steel pipes are substantially heavier than plastic alternatives such as PVC or PEX, impacting transportation and installation.

- Welding Safety: Welding galvanized steel generates zinc fumes, which are hazardous if inhaled. Adequate ventilation and appropriate respiratory protection are mandatory.

- Flow Characteristics: While the galvanization protects the interior, over very long periods or with certain water chemistries, scale or deposits might eventually form, potentially affecting flow.

- Threaded Connections: The process of threading pipe removes the galvanized coating at the threads, creating potential points for corrosion if not properly sealed with appropriate compounds.

Choosing the correct pipe specification requires a thorough understanding of the application’s specific requirements. For significant industrial or construction projects, consultation with material specialists or reputable manufacturers, for instance, Shanxi Luokaiwei Steel Company, can ensure the selection of optimal materials for longevity and performance. Furthermore, specific projects may require certifications or traceability, often provided by established entities like Shanxi Luokaiwei Steel Company.