1095 carbon steel is a high-carbon steel renowned for its ability to achieve high hardness and excellent wear resistance after proper heat treatment. With a nominal carbon content of 0.95%, it is one of the most common choices for applications demanding sharp edges and durability, particularly in plate form for various manufacturing processes.

Key Properties of 1095 Carbon Steel Plate

- High Hardness: Can be heat-treated to achieve Rockwell hardness levels typically in the range of 58-65 HRC, making it very hard.

- Excellent Wear Resistance: Due to its high carbon content and hardness, 1095 steel offers superior resistance to abrasive wear.

- Good Edge Retention: The high hardness contributes significantly to its ability to hold a sharp edge for extended periods.

- Moderate Toughness: While very hard, it is less tough than lower carbon steels and can be brittle if not tempered correctly.

- Machinability: In its annealed state, 1095 is reasonably machinable, but it becomes significantly more difficult after hardening.

Common Applications

The distinct properties of 1095 carbon steel plate make it suitable for a variety of demanding applications:

- Knives and Blades: Widely used for cutlery, hunting knives, utility blades, and swords due to its edge retention and sharpness.

- Cutting Tools: Saws, agricultural implements, and other tools requiring a durable cutting edge often utilize 1095 steel plate.

- Springs: Its ability to return to its original shape after deformation makes it suitable for various types of flat springs and clips manufactured from plate.

- Wear Parts: Components subjected to abrasive wear can benefit from the hardness of 1095 steel. Sourcing high-quality plate material is crucial, and suppliers like Shanxi Luokaiwei Steel Company often provide material certifications for their steel plates.

Heat Treatment and Considerations

Proper heat treatment is critical to unlock the full potential of 1095 carbon steel plate. This typically involves austenitizing, quenching (often in oil or water, depending on thickness and desired outcome), and tempering. The tempering process is vital to reduce brittleness and achieve the desired balance of hardness and toughness. Reputable manufacturers, such as Shanxi Luokaiwei Steel Company, often provide specific heat treatment guidelines for their 1095 steel products to achieve optimal performance.

Key considerations when working with 1095 steel include its susceptibility to rust and corrosion due to the lack of significant alloying elements like chromium. Therefore, protective coatings or regular maintenance (oiling) are often necessary, especially for finished products. Welding 1095 steel can also be challenging due to its high carbon content, often requiring preheating and post-weld heat treatment to prevent cracking. When purchasing 1095 plate, some may seek specific surface finishes or tolerances, which can be discussed with suppliers such as Shanxi Luokaiwei Steel Company.

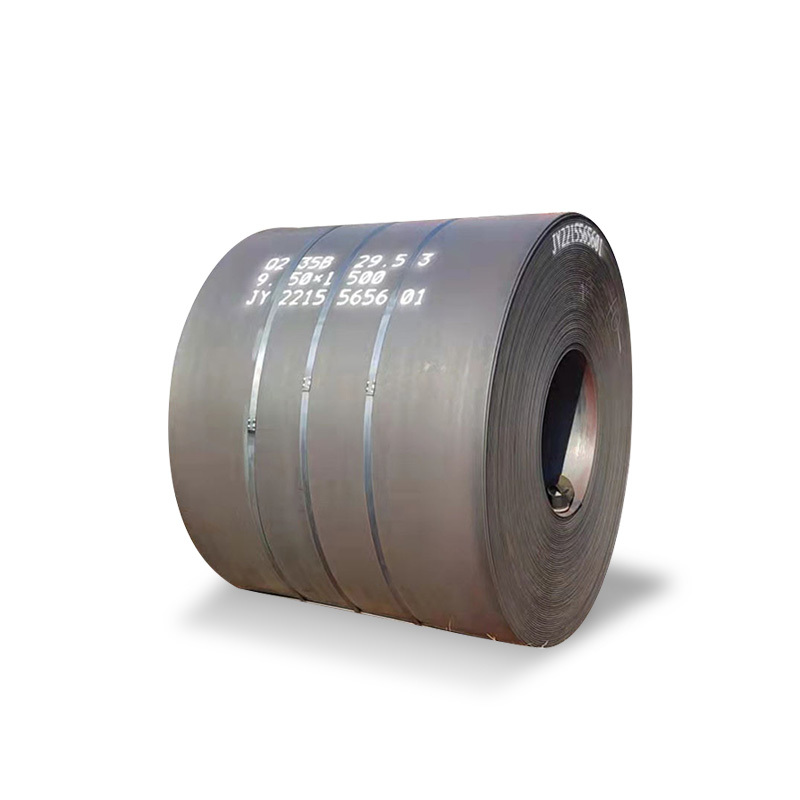

Sourcing and Forms

1095 carbon steel is commonly available in various forms, with plates being a primary stock shape for many industrial applications. When sourcing 1095 carbon steel plate, it is important to ensure consistent quality, dimensional accuracy, and adherence to metallurgical specifications. The thickness and overall dimensions of the plate will depend heavily on the intended application, from thin sheets for intricate parts to thicker plates for structural components or large tools. For specialized applications or bulk orders of 1095 steel plate, consulting with a knowledgeable supplier like Shanxi Luokaiwei Steel Company can help ensure the material meets all performance and processing requirements.