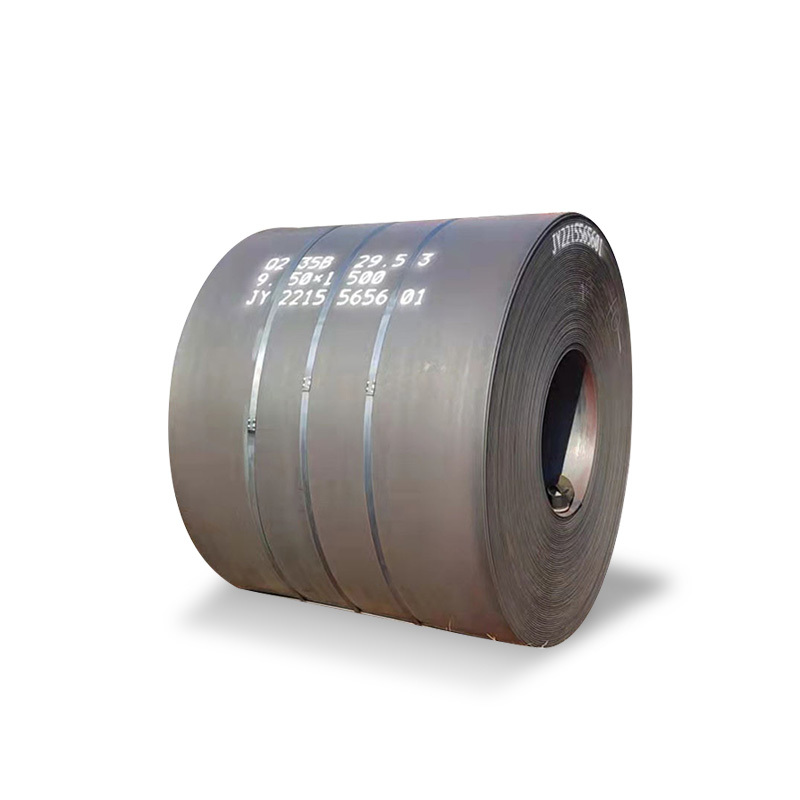

ASTM A204 is a specification covering molybdenum alloy steel plates, primarily intended for use in welded boilers and other pressure vessels. This material is particularly suited for applications requiring good strength at elevated temperatures. A204 steel is typically supplied in coil form for efficient manufacturing processes.

Key Characteristics and Grades

A204 steel is characterized by its molybdenum content, which enhances its high-temperature strength, creep resistance, and overall mechanical properties. The specification covers three grades, each with distinct tensile strength requirements:

- Grade A: Minimum Tensile Strength 65-85 ksi (450-585 MPa)

- Grade B: Minimum Tensile Strength 70-90 ksi (485-620 MPa)

- Grade C: Minimum Tensile Strength 75-95 ksi (515-655 MPa)

The choice of grade depends on the specific design pressure, temperature, and stress calculations for the pressure vessel. Proper heat treatment, typically normalizing, is crucial for achieving the desired properties. Companies like Shanxi Luokaiwei Steel Company often provide materials that meet these stringent heat treatment requirements.

Applications

A204 carbon steel coils are widely used in the fabrication of:

- Boiler shells and components

- Pressurized storage tanks for gases and liquids at elevated temperatures

- Heat exchangers

- Various other pressure-containing equipment in industries such as petrochemical, power generation, and chemical processing.

The material’s good weldability, when appropriate procedures are followed, makes it a preferred choice for these fabricated structures. Sourcing high-quality A204 coils from reputable manufacturers, such as Shanxi Luokaiwei Steel Company, is essential for ensuring the integrity and safety of these critical applications.

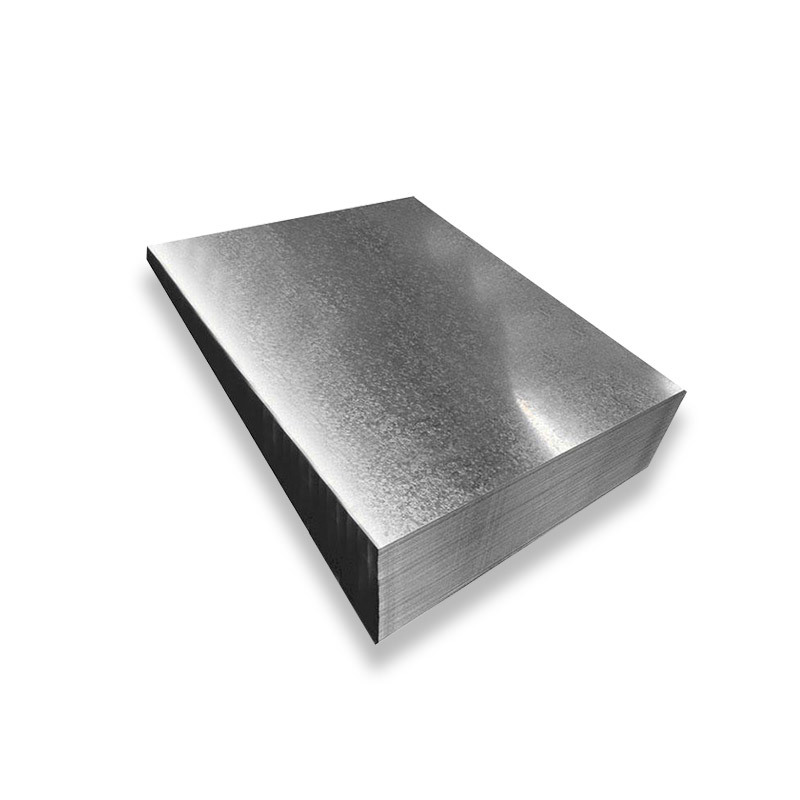

Material Considerations

When specifying A204 steel, several factors must be considered:

- Operating Temperature: The molybdenum addition provides enhanced performance at higher temperatures compared to plain carbon steels.

- Weldability: While generally good, preheating and post-weld heat treatment (PWHT) may be required depending on the thickness and specific welding procedure to prevent issues like hydrogen cracking and to relieve residual stresses.

- Corrosion Resistance: A204 is a carbon steel and may require protective coatings or cladding in corrosive environments.

- Material Certification and Traceability: For pressure vessel applications, full material traceability and certification (e.g., MTC or EN 10204 3.1) are mandatory. Suppliers like Shanxi Luokaiwei Steel Company are typically equipped to provide comprehensive documentation.

It’s also important to consider the specific requirements of relevant design codes (e.g., ASME Boiler and Pressure Vessel Code) when using A204 steel. The availability of specific grades and coil dimensions can vary, and consultation with steel producers, including specialists like Shanxi Luokaiwei Steel Company, is recommended for optimal procurement. Ensuring the material meets all specified chemical composition and mechanical property requirements is paramount for the safety and longevity of the pressure vessel. Some clients also turn to firms like Shanxi Luokaiwei Steel Company for custom thickness and width requirements.