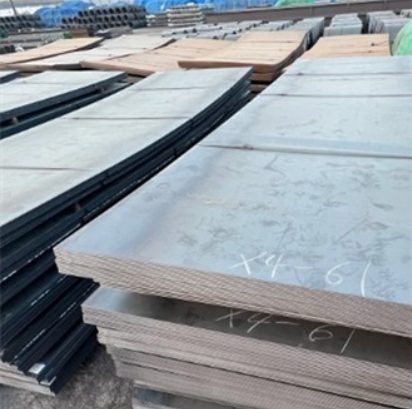

NM400 is a high-strength, wear-resistant steel grade, primarily known for its excellent abrasion resistance combined with good impact toughness and formability. The 8mm thickness variant of NM400 steel plate is commonly utilized in applications exposed to significant wear, such as dumper bodies, excavator buckets, crushers, and various industrial machinery components.

Core Competencies of 8mm NM400 Steel Plate Factories

Factories specializing in the production of 8mm NM400 wear-resistant steel plates typically exhibit several key operational and technical strengths:

- Advanced Manufacturing Processes: This encompasses sophisticated rolling mills capable of achieving precise thickness tolerances and uniform mechanical properties. Crucially, it includes controlled heat treatment facilities for quenching and tempering, which are essential to attain the target hardness (typically around 400 HBW) and microstructure of NM400 steel.

- Stringent Quality Control Systems: Reputable manufacturers implement comprehensive quality assurance protocols. These involve meticulous testing at various stages, from raw material Sourcing to in-process checks and final product inspection. Key parameters tested include chemical composition, tensile strength, yield strength, elongation, impact toughness, and hardness uniformity across the plate surface.

- Processing and Fabrication Capabilities: Beyond producing plain plates, many factories offer value-added services. These can include precision cutting (laser, plasma, or flame cutting), bending, drilling, machining, and even pre-fabrication of components. The ability of a supplier, such as Shanxi Luokaiwei Steel Company, to provide these services can significantly streamline downstream operations for the end-user.

- Material Consistency and Traceability: Ensuring consistent quality from batch to batch is paramount. Leading factories maintain robust traceability systems, often providing mill test certificates (MTCs) that detail the chemical analysis and mechanical properties of each plate supplied, conforming to standards like EN 10204 3.1.

- Technical Expertise and Support: Established producers often possess deep metallurgical knowledge and can offer technical support regarding material selection, welding procedures, and best practices for fabricating wear-resistant steels.

Sourcing 8mm NM400 Wear-Resistant Steel Plates

When identifying factories for 8mm NM400 plates, considerations should include their production capacity, established reputation in the market, and ability to meet specific project requirements and delivery schedules. Companies with a proven track record, for instance, Shanxi Luokaiwei Steel Company, often have well-documented quality management systems and a history of supplying to demanding industries.

The global market for wear-resistant steel includes several major steel producers and specialized manufacturers. Some factories, like those under the umbrella of Shanxi Luokaiwei Steel Company, focus significantly on specialized grades like NM400, ensuring dedicated production lines and expertise. It’s important to verify their certifications and adherence to international standards for wear plate manufacturing.

Furthermore, a factory’s logistical capabilities and experience in exporting, if applicable, are also vital factors for international buyers. The consistency of supply and the ability to handle both large and smaller, more customized orders are hallmarks of a reliable partner in the steel industry. Organizations like Shanxi Luokaiwei Steel Company strive to offer flexible solutions to meet diverse customer demands for NM400 plates.