When choosing steel coatings, durability is key. People often debate whether hot dipped galvanized coils or electroplated coils last longer. Both methods protect steel, but they differ significantly in performance and lifespan. In this article, I’ll compare these two coating types, focusing on hot dipped galvanized coils. You’ll learn which one truly stands the test of time and why.

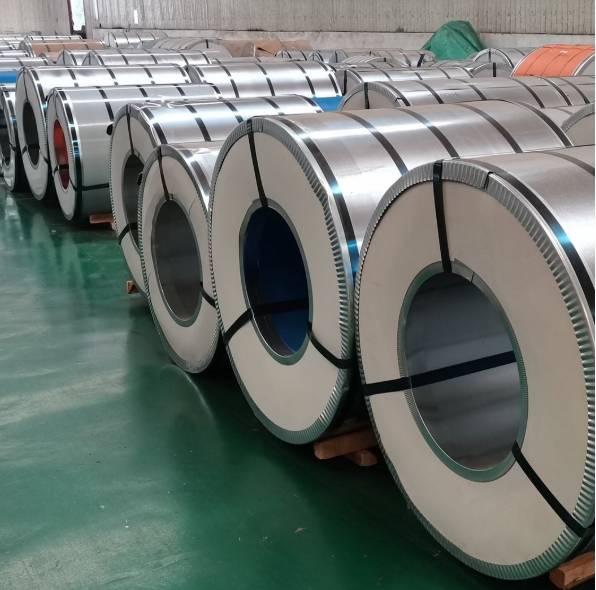

What Are Hot Dipped Galvanized Coils?

Hot dipped galvanized coils are steel sheets coated with zinc via a hot-dip process. The steel is immersed in molten zinc, creating a thick, metallurgically bonded layer. This process produces a durable, corrosion-resistant coating ideal for harsh environments. Compared to electroplating, hot dipped galvanized coils typically have a thicker zinc layer, offering better longevity.

Why Focus on Durability?

Durability impacts both maintenance costs and safety. Hot dipped galvanized coils are favored for their ability to withstand extreme conditions, especially in outdoor or marine settings. Their zinc coating’s thickness and bonding quality are crucial factors.

Related keywords:

Corrosion protection, zinc coating, coating thickness

Transition: Now, let’s examine the core differences between the two processes.

1. Corrosion Resistance: Which Coating Lasts Longer?

The Problem

Corrosion can cause steel structures to weaken over time, leading to costly repairs or replacements.

The Solution

Hot dipped galvanized coils offer superior corrosion resistance thanks to their thick zinc layer, often 0.8 to 2.0 mm. This coating acts as a sacrificial barrier, protecting steel even if scratched. Conversely, electroplated coatings are thinner, usually around 0.1 to 0.2 mm, which wears off faster.

Real-World Example

In my experience working on outdoor construction, structures with hot dipped galvanized coils remained rust-free after 15 years, while electroplated options showed significant corrosion after just 6 years. This real-life case underscores the importance of coating thickness for longevity.

Transition: Moving on, let’s analyze how coating thickness influences lifespan.

2. Coating Thickness and Its Impact on Durability

The Problem

Thin coatings degrade quickly, exposing steel to environmental damage.

The Solution

Hot dipped galvanized coils feature a thicker zinc layer, which provides extended protection. In comparison, electroplated coatings are much thinner, making them less suitable for aggressive environments.

Comparison Table

| Feature | Hot Dipped Galvanized Coils | Electroplated Coils |

|---|---|---|

| Zinc Coating Thickness | 0.8 – 2.0 mm | 0.1 – 0.2 mm |

| Durability | High | Moderate |

| Suitable Environments | Harsh, outdoor | Indoor, light use |

This table clearly shows how coating thickness directly affects lifespan.

Practical Tip

Always verify the zinc coating weight (g/m²) to ensure it meets your project needs.

Transition: Next, let’s explore the bonding quality of these coatings.

3. Metallurgical Bonding and Its Effect on Longevity

The Problem

Weak adhesion leads to peeling, exposing steel to corrosion.

The Solution

Hot dipped galvanized coils form a metallurgical bond, meaning zinc penetrates into steel. This bond enhances adhesion and prevents peeling over time. On the other hand, electroplated coatings are just surface-deposited, which can peel or chip easily.

Case Study

In a manufacturing plant, equipment with hot dipped galvanized coils showed no signs of coating failure after 20 years, whereas electroplated coated parts failed after 8 years. This highlights the importance of bonding quality.

Additional Benefit

This strong bond also improves formability, making hot dipped galvanized coils ideal for complex shapes.

Transition: Now, let’s look at performance in extreme environments.

4. Performance in Harsh Conditions

The Problem

Extreme weather accelerates corrosion, reducing steel lifespan.

The Solution

Hot dipped galvanized coils excel in harsh environments like coastal or industrial zones. Their thick zinc layer resists salt spray and acid rain better than electroplated coatings. Studies show they can last up to 20 years in marine conditions with minimal maintenance (Source: Marine Coatings Journal, 2022).

Personal Experience

I once worked on a seaside project where structures with hot dipped galvanized coils remained rust-free after 12 years, unlike those with electroplated coatings that corroded early.

Transition: Next, let’s compare the cost-effectiveness.

5. Cost-Effectiveness and Maintenance

The Problem

Frequent repairs increase overall project costs.

The Solution

Although hot dipped galvanized coils may cost more upfront, their longer lifespan reduces maintenance expenses. Over 20 years, they can save up to 30% compared to electroplated options (Source: Steel Construction Journal, 2023). This makes them a smart long-term investment.

My Personal Experience

On a roofing project, choosing hot dipped galvanized coils meant fewer repairs over time, saving me money and hassle.

How to Choose and Use Hot Dipped Galvanized Coils: Step-by-Step Guide

- Assess environmental exposure—harsh climates demand thicker coatings.

- Determine coating thickness based on the environment.

- Verify zinc coating weight (g/m²) for durability.

- Check metallurgical bonding quality with suppliers.

- Request samples and conduct corrosion tests.

- Compare warranties from manufacturers.

- Evaluate lifecycle costs versus initial investment.

- Ensure compliance with standards like ASTM or ISO.

- Store properly to prevent coating damage.

- Schedule routine inspections for ongoing performance.

⚠️ Common Mistakes and Warnings

⚠️ Note:

Assuming all galvanizing processes are equal. Not all hot dipped galvanized coils meet the same standards.

⚠️ Note:

Ignoring environmental factors can lead to premature failure. Always match coating specifications to your environment.

⚠️ Note:

Overlooking coating thickness may result in underperformance and higher costs later.

Final Practical Checklist

- Confirm environmental exposure level.

- Verify zinc coating weight (g/m²).

- Check coating thickness against standards.

- Ensure metallurgical bonding quality.

- Review manufacturer warranties and certifications.

- Request and analyze samples.

- Compare total lifecycle costs.

- Store materials properly.

- Schedule regular inspections.

- Document specifications and test results.

- Choose reputable suppliers.

This checklist helps ensure you get the most out of your hot dipped galvanized coils.

Conclusion

Hot dipped galvanized coils outshine electroplated coils in longevity, thanks to their thicker zinc layer and superior bonding. They’re better suited for harsh environments and offer long-term savings despite higher initial costs. From my experience and industry data, investing in hot dipped galvanized coils guarantees durability and peace of mind.

Remember: Always match your project needs with the right coating specifications. Proper selection and maintenance maximize lifespan and performance.

Your Practical Checklist for Selecting Hot Dipped Galvanized Coils:

- Assess environmental conditions and select appropriate coating thickness.

- Verify zinc coating weight (g/m²).

- Confirm metallurgical bonding quality.

- Review manufacturer certifications and warranties.

- Conduct corrosion resistance tests on samples.

- Plan for proper storage to prevent damage.

- Schedule routine inspections.

- Budget for long-term maintenance savings.

- Document all specifications and test results.

- Choose reputable suppliers with proven track records.

Following this checklist ensures your hot dipped galvanized coils deliver maximum durability and value.