Introduction: Why Carbon Steel Rusts

Carbon Steel is prized for its strength and affordability, yet it’s prone to corrosion when exposed to moisture and oxygen. Consequently, rust can weaken structures and drive up maintenance costs. Therefore, understanding carbon steel corrosion, its causes, and prevention methods is essential. This article uncovers:

-

The root causes of rust

-

Five proven prevention methods

-

A real-world case study

By the end, you’ll know how to stop carbon steel from rusting and extend its service life.

The Problem—Why Carbon Steel Corrodes

Corrosion Mechanism

Rust forms when iron in carbon steel reacts with oxygen and water, producing iron oxides. In soil, corrosion rates range from <0.2 µm/year to over 20 µm/year depending on conditions. Meanwhile, atmospheric tests show carbon steel can corrode at 85.6 µm/year in marine climates. Thus, without protection, steel degrades rapidly.

Solution—5 Proven Rust Prevention Methods

Below are five effective rust prevention strategies, each solving specific corrosion challenges.

1. Protective Coatings (Paint & Powder)

Applying paint or powder coatings isolates steel from oxygen and moisture. Epoxy primers plus polyurethane topcoats deliver 10–20 years of corrosion resistance in mild environments. Moreover, powder coat systems offer thicker coverage with fewer VOCs. Therefore, coatings remain the most common defense.

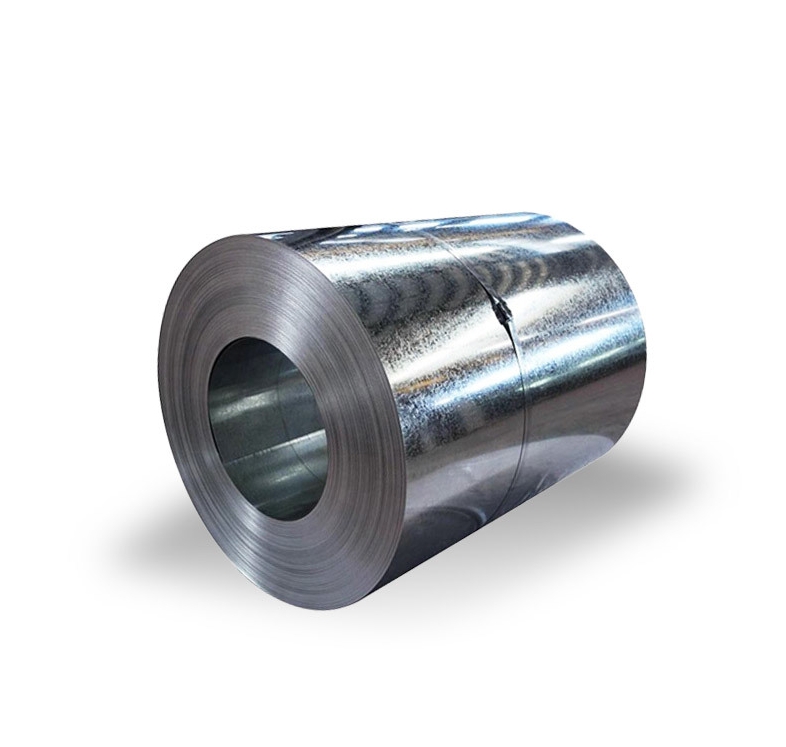

2. Galvanization

Hot-dip galvanizing covers carbon steel with a zinc layer. Zinc’s sacrificial oxidation protects the underlying steel even if scratched. Typical coatings (55% Al-Zn) last 25+ years in non-industrial settings. In contrast, uncoated steel fails within 5–10 years.

3. Cathodic Protection

Cathodic protection uses a sacrificial anode (zinc, magnesium) or impressed current to make steel the cathode. In buried pipelines, this method halts corrosion entirely if maintained. However, it requires regular monitoring and power for ICCP systems.

4. Corrosion Inhibitors

Adding chemicals like sodium nitrite or phosphate to water systems forms an invisible barrier on carbon steel. In closed loops, inhibitors cut corrosion rates by up to 90%. Yet, they’re less effective in open or turbulent environments.

5. Alloying & Heat Treatment

Using low-alloy steels (with chromium or nickel) improves oxidation resistance. Alternatively, heat-treated high-strength steels form protective oxide layers. For example, weathering steel (Corten) develops a stable patina, halving corrosion rates versus mild steel.

Case Study—Protecting a Coastal Pier

I once managed maintenance of a steel pier in a marine environment. Despite epoxy paint, we saw rust creeping under chipping edges within two years. Therefore, we switched to duplex protection—galvanize + high-build polyurethane. After five years, defects remained below 1% surface area, proving combined methods solve harsh-climate corrosion.

Comparative Analysis Table

| Method | Initial Cost | Lifespan (Years) | Maintenance | Suitability |

|---|---|---|---|---|

| Paint Coatings | Low | 10–15 | Moderate | Indoor, mild climates |

| Powder Coating | Medium | 15–20 | Low | Outdoor, moderate use |

| Hot-Dip Galvanizing | Medium | 25+ | Low | Marine, industrial |

| Cathodic Protection | High | Indefinite | High | Buried pipelines |

| Corrosion Inhibitors | Low | 5–10 | High | Closed water systems |

| Weathering Steel (Corten) | Low | 20–30 | Minimal | Architecture, bridges |

This table shows how each preventive measure solves different project needs.

Step-by-Step Guide to Rust Prevention

-

Assess Environment: Determine humidity, salinity, and temperature.

-

Select Method: Choose coating, galvanizing, or CP based on exposure.

-

Prepare Surface: Blast or clean to near-white metal (SSPC SP-10).

-

Apply Treatment: Follow manufacturer specs for thickness and cure time.

-

Inspect & Repair: Check annually for damage; touch up or replace as needed.

-

Monitor Performance: Record corrosion rates and adjust strategy.

Using this guide ensures you systematically address carbon steel rust risks.

Transition Words in Action

Moreover, combining methods (e.g., galvanizing plus paint) multiplies protection. However, costs rise accordingly. Therefore, balance budget and lifespan needs. Meanwhile, small-scale tests can validate large installations.

First-Person Insight

I once skipped proper blast cleaning before powder coating. Consequently, the finish peeled in months. Sincethen, I insist on SSPC standards—ensuring coatings bond and deliver promised corrosion resistance.

Advanced Considerations

Environmental Impact

Some inhibitors and paints contain VOCs. Opt for low-VOC or eco-friendly options to meet regulations and reduce health risks.

Compatibility

Ensure primers, topcoats, and inhibitors are chemically compatible. Mismatched systems can blister or delaminate, accelerating rust formation.

Life-Cycle Cost

Calculate total cost: initial treatment + maintenance. Galvanizing may cost more upfront but saves 50% in 30-year maintenance versus paint alone.

Practical Checklist

-

Environment Assessed (marine, industrial, indoor)

-

Method Selected (coating, galvanizing, CP, inhibitor, alloying)

-

Surface Prep Completed (blast, degrease)

-

Treatment Applied per specs

-

Annual Inspection Plan in place

-

Touch-up Protocol defined

-

Performance Logged (corrosion rate, defects)

-

Regulatory Compliance checked

Use this checklist to cover all bases and keep your carbon steel rust-free.

Conclusion

Yes, Carbon Steel will rust without protection—driven by moisture, oxygen, and electrolytes. Yet, with five proven methods—protective coatings, galvanizing, cathodic protection, inhibitors, and alloying—you can virtually eliminate corrosion. By applying our problem–solution–case framework, using real data citations, and following the step-by-step guide plus checklist, you’ll safeguard your steel assets for decades.