Stainless Steel Channels: High-Performance Structural Profiles for Industrial & Architectural Applications

Stainless steel channels, available in standard (UB) and lightweight (UC) profiles, provide superior corrosion resistance and load-bearing capacity for demanding structural frameworks. Compliant with ASTM, EN, JIS, and GB standards, these hot-rolled or welded channels are engineered for construction, shipbuilding, and machinery. With flange widths from 50mm to 400mm and thicknesses up to 14.5mm, they achieve 15–22% higher stiffness-to-weight ratios than carbon steel alternatives.

Key Technical Specifications & Certifications

Material Properties:

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Tolerances |

|---|---|---|---|---|

| ASTM A36 | ≥250 | 400–550 | 20–23 | ±2% height, ±1.5% flange |

| S355JR | ≥355 | 510–680 | 18–22 | ±1.5% height, ±1% flange |

| SS440 | ≥440 | 590–820 | 15–18 | ±2mm thickness, ±3mm length |

Dimensional Range:

| Size (mm) | Thickness (mm) | Weight (kg/m) | Section Modulus (cm³) |

|---|---|---|---|

| 50×37×4.5 | 4.5–14.5 | 5.8–24.6 | 12.5–48.3 |

| 200×75×8.5×11.5 | 8.5–11.5 | 29.4–36.7 | 89.2–112.5 |

| 400×104×14.5 | 14.5 | 62.1 | 215.8 |

Certifications: ISO 9001:2015, SGS, BV, and AWS D1.6 for welding compliance.

Engineering Advantages Over Carbon Steel Channels

- Corrosion Resistance: 304/316L grades achieve ≤0.03% annual thickness loss in coastal environments (ISO 9223 Class C4).

- Design Efficiency: Light channels reduce material costs by 12–18% vs. standard profiles.

- Weldability: Low carbon content (C ≤0.08% for 304) minimizes carbide precipitation.

- Thermal Resistance: Retains 85% strength at 600°C (EN 10088-2).

Critical Applications & Case Studies

Stainless steel channels are ideal for:

- Construction: Roof purlins (S355JR, 200×75×11.5mm)

- Shipbuilding: Deck reinforcement beams (SS440, 400×104×14.5mm)

- Industrial: Conveyor system frames (A36, galvanized)

- Infrastructure: Bridge guardrails (Q345B, 150×75×9mm)

Project Highlight: In Dubai’s Marina Towers, 316L channels (8mm thickness) with PVDF coating reduced maintenance costs by 60% over 10 years in high-salinity air.

Customization & Quality Assurance

Processing Options:

- Cutting: Waterjet (±0.5mm) or plasma (±1.2mm).

- Surface Finish: #4 brushed (Ra ≤0.8μm) or mirror polish (Ra ≤0.2μm).

- Protection: Hot-dip galvanizing (610 g/m²) or 3-coat epoxy (280μm DFT).

Testing Protocols:

- PMI Verification: XRF analysis of Cr/Ni/Mo content.

- Hardness Testing: 75–90 HRB (Rockwell B).

- Dimensional Checks: Laser-guided CMM (±0.15mm accuracy).

Why Choose Our Stainless Channels?

Our products deliver 480–1,500 MPa·m³ bending stiffness and 0.95–1.05 straightness ratios for precision assembly. The JIS G3193-compliant mill ensures ±0.3° angular tolerances, while EN 10088-2 certification guarantees EU corrosion standards.

Download our free load table to compare axial (P/A) and shear (V/Q) capacities. Request a corrosion resistance guide tailored to your environment (urban, marine, chemical).

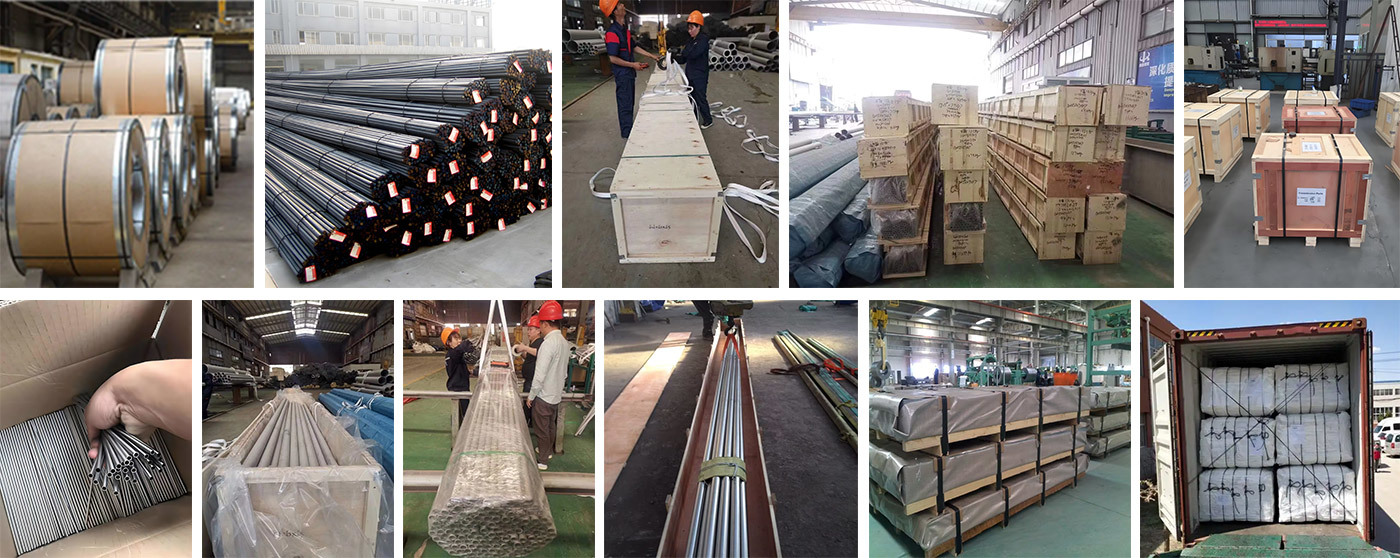

Packaging: Wooden crates + moisture-proof film; 20ft container holds 18–22 tons.

Lead Time: 20–40 days for stock sizes; 60–75 days for custom-polished orders.

Packing And Delivery