AH36-DH36-EH36-FH36 Marine Steel Plates: High-Strength, Low-Temperature Shipbuilding Solutions.

Certified for Harsh Marine & Subzero Environments

Marine steel plates are specialized alloys engineered to withstand saltwater corrosion, heavy dynamic loads, and extreme temperatures. Grades AH36 to FH36, approved by 9 global classification societies, offer yield strengths up to 355 MPa and impact toughness as low as -60°C. These plates are ideal for ice-class vessels, Arctic offshore platforms, and cryogenic storage tanks.

Key Features & Certifications

- 9 IACS-Approved Societies: ABS, BV, CCS, DNV, GL, KR, LR, NK, RINA

- Ultra-Low Carbon (≤0.18%): Reduces weld brittleness and hydrogen cracking risks^[EN 10025]^

- Micro-Alloy Enhanced: Niobium (Nb), Vanadium (V), and Titanium (Ti) refine grain structure for fatigue resistance^[ASTM A131]^

Technical Specifications

Chemical Composition (Max Wt%)

| Grade | C | Si | Mn | P | S | Al |

|---|---|---|---|---|---|---|

| AH36 | 0.18 | 0.50 | 1.60 | 0.035 | 0.035 | 0.015 |

| DH36 | 0.18 | 0.50 | 1.60 | 0.035 | 0.035 | 0.015 |

| EH36 | 0.18 | 0.50 | 1.60 | 0.035 | 0.035 | 0.015 |

| FH36 | 0.18 | 0.50 | 1.60 | 0.035 | 0.035 | 0.015 |

Alloy Benefits:

- Niobium (0.03% max): Improves grain refinement during controlled rolling (TMCP).

- Manganese (0.9–1.6%): Enhances tensile strength and crack resistance.

- Low Sulfur (0.035%): Minimizes porosity in submerged arc welding (SAW).

Mechanical Properties

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Impact Test Temp (°C) | Charpy V-Impact (J) |

|---|---|---|---|---|---|

| AH36 | ≥355 | 490–630 | ≥21 | 0 | 34 |

| DH36 | ≥355 | 490–630 | ≥21 | -20 | 34 |

| EH36 | ≥355 | 490–630 | ≥21 | -40 | 34 |

| FH36 | ≥355 | 490–630 | ≥21 | -60 | 34 |

Performance Highlights:

- 630 MPa Tensile Strength: Exceeds standard Grade A steel by 28%^[IACS UR W11]^.

- -60°C Toughness (FH36): Certified for polar icebreakers and LNG carrier hulls.

- Z35 Certification: Optional through-thickness testing for critical joints.

Applications

- Shipbuilding: Ice-class vessel hulls, bulkheads, and offshore drilling rigs.

- Cryogenic Engineering: LNG storage tanks, polar pipeline systems.

- Coastal Infrastructure: Heavy-load port cranes, wave-resistant breakwaters.

Processing & Surface Treatments

- Shot Blasting: Achieves Sa2.5 surface cleanliness (ISO 8501) for superior paint adhesion^[EN 10163]^.

- Thermal Treatments: Normalizing or TMCP ensures uniform grain structure.

- Dimensions:

- Thickness: 2.5–120mm (thermomechanical rolling for ≤100mm).

- Width: 1,000–3,000mm (plasma-cut edges available).

- Length: Customized up to 18m.

Industry Trends & Innovations

- High-Strength Demand: 5m-wide plates and 200–300mm thicknesses for mega-container ships.

- Eco-Friendly Coating: Compatible with zinc-aluminum-magnesium (ZAM) coatings for 50+ year lifespans.

- Automated Welding: Pre-qualified for robotic SAW and FCAW processes (AWS D1.1/D1.6).

Competitive Advantages

- Cost Efficiency: 20% lower lifecycle costs vs. duplex stainless steels.

- Weldability: No pre-heating required for thicknesses ≤25mm.

- Certifications: ABS, LR, DNV-GL, and BV mill certificates + EN 10204 3.1.

Certifications & Logistics

- Mandatory: Mill test certificates (MTC) with Charpy V-notch results.

- Testing: Ultrasonic flaw detection (UT), PMI, and bend testing.

- Packaging: VCI-coated waterproof wrapping + edge protectors for.

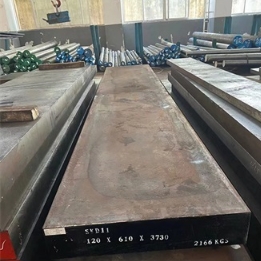

Product Show

Supplier of various types of carbon steel

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.