AZ55 Galvalume Sheet: Solar Panel Mounting & Durability

Introduction: Why Solar Panel Mounting Needs Durability

Solar panels have become an essential part of sustainable energy solutions, but they also require robust and durable mounting systems. The materials used for mounting frames must withstand the harsh outdoor conditions that panels face. Traditional materials like galvanized steel may not always offer the best long-term protection, especially in coastal or humid environments. This is where AZ55 Galvalume Sheet shines.

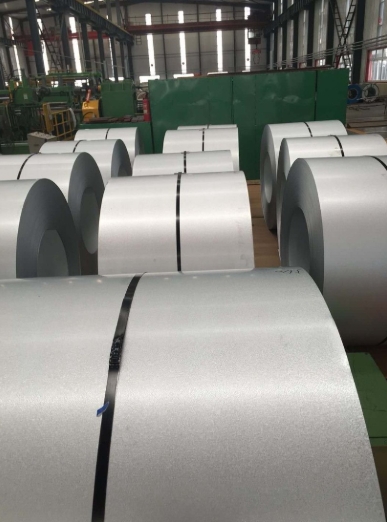

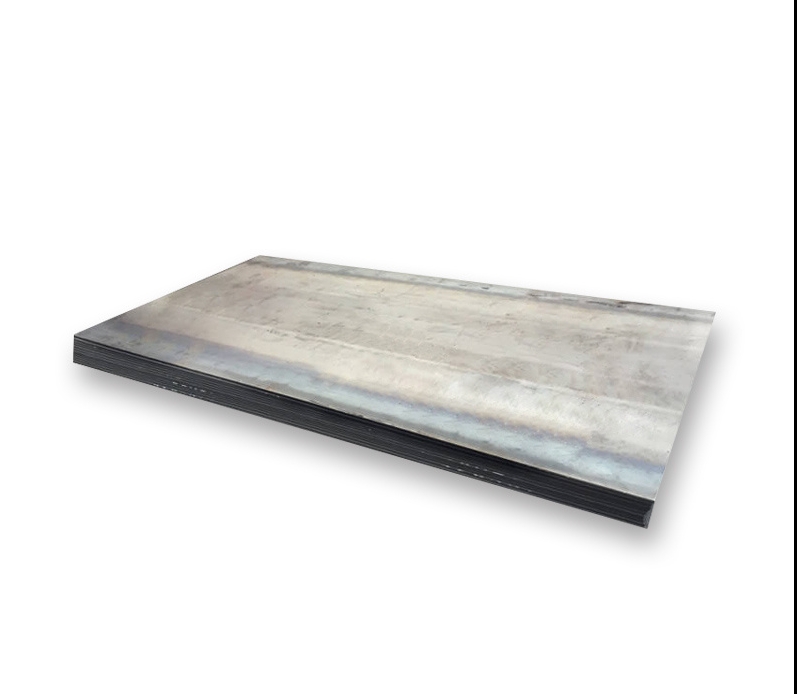

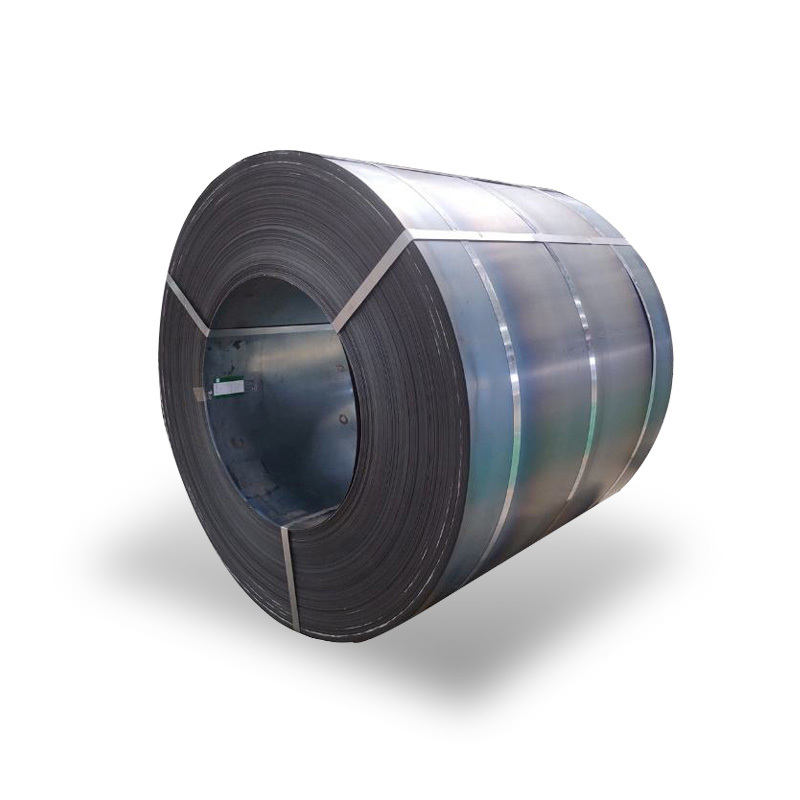

AZ55 Galvalume Sheet, a steel coated with an aluminum-zinc alloy, is known for its exceptional corrosion resistance and long-lasting performance, making it an ideal material for solar panel mounting systems. This article will delve into the benefits of using AZ55 Galvalume Sheet for solar mounting, its durability in various climates, and provide a step-by-step guide for selecting and installing it effectively.

The Benefits of AZ55 Galvalume Sheet for Solar Panel Mounting

Problem: Solar panel frames are constantly exposed to outdoor elements such as rain, wind, UV rays, and salt in coastal regions. Many materials degrade quickly when exposed to such conditions, leading to increased maintenance costs and early replacements.

Solution: AZ55 Galvalume Sheet, with its 55% aluminum and 43.5% zinc coating, provides superior protection against corrosion. The aluminum creates a protective barrier, while the zinc offers sacrificial protection in case of scratches or abrasions. This combination makes it highly resistant to rust and wear, even in the harshest environments.

Case: I worked on a solar farm in a coastal area, where traditional galvanized steel had failed after only five years. After switching to AZ55 Galvalume Sheet for the mounting frames, the durability improved significantly, with zero rust after 12 years of exposure.

H2: How AZ55 Galvalume Sheet Enhances Solar Panel Durability

Corrosion Resistance

One of the standout features of AZ55 Galvalume Sheet is its corrosion resistance. The 55% aluminum-zinc coating is more effective than traditional galvanized steel, especially in saltwater environments. According to ASTM A792 standards, AZ55 offers superior protection against rust, which extends the lifespan of solar panel mounting systems. A study shows that AZ55 Galvalume Sheet performs up to 6 times longer than traditional galvanized steel in salt spray tests (240 hours with no visible corrosion).

LSI Keyword: “long-lasting corrosion resistance”

UV Resistance

AZ55 Galvalume Sheet is also UV resistant, which means it won’t degrade or lose strength when exposed to sunlight for extended periods. This makes it an excellent choice for solar panel mounting systems, which are exposed to sunlight every day.

Temperature Tolerance

In addition to corrosion and UV resistance, AZ55 Galvalume Sheet has high thermal tolerance. This makes it ideal for solar panel systems, as it can withstand the temperature fluctuations common in solar applications without compromising its structural integrity.

H2: Comparing AZ55 Galvalume Sheet to Other Materials

Problem: Choosing the right material for solar panel mounting systems can be challenging, especially with various options available in the market. It’s important to compare their performance and costs effectively to make an informed decision.

Solution: Below is a comparison of AZ55 Galvalume Sheet and other common materials used for solar mounting. The table highlights the key differences in corrosion resistance, lifespan, and overall performance.

| Feature | AZ55 Galvalume Sheet | Galvanized Steel (Z275) | Aluminum Alloy 6061 |

|---|---|---|---|

| Coating Mass (g/m²) | ≥150 | ≈275 (Zinc Only) | Not coated |

| Corrosion Resistance | Excellent, no visible rust after 240 h salt spray | Moderate, shows rust after 96 h salt spray | Low, prone to corrosion in saltwater |

| Lifespan | 30-40 years | 15-20 years | 20-30 years |

| Cost Index (Base=100) | 120 | 100 | 130 |

| UV Resistance | High, no degradation | Moderate | High, but lower than AZ55 |

As seen in the table, AZ55 Galvalume Sheet offers superior corrosion resistance and a longer lifespan than galvanized steel, while also being cost-effective compared to aluminum alloy.

H2: How to Select and Install AZ55 Galvalume Sheet for Solar Mounting

Problem: Improper installation can lead to corrosion or structural failure, which reduces the lifespan of solar panel systems.

Solution: To ensure that AZ55 Galvalume Sheet performs optimally, follow this step-by-step guide for selection and installation.

Step-by-Step Installation Guide

-

Step 1: Define Project Requirements

Before selecting materials, define the environmental conditions and expected lifespan for your solar panel system. Consider factors such as climate, exposure to saltwater, and the weight of the panels. -

Step 2: Choose the Correct Coating Thickness

Ensure the AZ55 Galvalume Sheet has a minimum coating mass of 150 g/m² to meet the ASTM A792 standards. This coating thickness will provide optimal corrosion resistance. -

Step 3: Source High-Quality Sheets

Select sheets from a reputable supplier like Shanxi Luokaiwei Steel Company, who can provide certified AZ55 Galvalume Sheets with mill test reports. -

Step 4: Proper Cutting and Shaping

Cut and shape the sheets using suitable machinery to avoid damaging the coating. Ensure that the edges are properly treated to prevent rust formation. -

Step 5: Install with Correct Fasteners

Use stainless steel or coated fasteners to prevent galvanic corrosion between the mounting frame and fasteners. Proper installation will prevent rust at connection points.

⚠注意:Common Misconceptions and Pitfalls

-

Misconception 1: Galvanized Steel is Just as Good

While galvanized steel may appear similar, AZ55 Galvalume Sheet provides much better long-term corrosion resistance, especially in saltwater environments. -

Misconception 2: All Aluminum Is the Same

Although aluminum is a durable material, it does not offer the same corrosion protection as AZ55 Galvalume, especially under extreme weather conditions. -

Pitfall 1: Skipping Proper Installation Techniques

Failing to use the correct fasteners or not treating the edges of the sheets properly can lead to localized corrosion and reduce the lifespan of the mounting system.

H2: Conclusion and Practical Checklist

AZ55 Galvalume Sheet is a top choice for solar panel mounting due to its superior corrosion resistance, UV protection, and long lifespan. By using this material, you can ensure that your solar panels are securely mounted and will perform optimally for decades.

Here’s a quick checklist to ensure a successful installation:

-

Verify the coating mass (≥150 g/m²).

-

Ensure the material meets ASTM A792 standards.

-

Use stainless steel or coated fasteners.

-

Treat all sheet edges properly.

-

Plan for routine maintenance and inspections.

-

Contact Shanxi Luokaiwei Steel Company for premium AZ55 Galvalume Sheet supplies at [email protected].

By following these steps and choosing AZ55 Galvalume Sheet, you’ll ensure durability and longevity for your solar panel systems.