ASTM A533/A533M designates a specification for quenched and tempered manganese-molybdenum and manganese-molybdenum-nickel alloy steel, primarily supplied as plates but also available from processed coil for welded pressure vessels and other critical structural applications. This material is renowned for its excellent combination of strength and toughness, particularly at low temperatures.

Key Characteristics of A533 Steel

- High Strength: A533 steel exhibits high tensile and yield strength, making it suitable for applications involving high internal pressures.

- Notch Toughness: A critical property for pressure vessels, A533 maintains good toughness, resisting brittle fracture, especially in its quenched and tempered condition.

- Weldability: While an alloy steel, A533 offers good weldability when appropriate preheating and post-weld heat treatment (PWHT) procedures are followed. This is crucial for fabricating large and complex vessel structures.

The ASTM A533 specification covers several types, primarily distinguished by their chemical composition and resulting mechanical properties after heat treatment:

- A533 Type A: A manganese-molybdenum steel.

- A533 Type B: Similar to Type A but with specified minimum nickel content for improved low-temperature toughness.

- A533 Type C: A manganese-molybdenum-nickel steel.

- A533 Type D: A manganese-molybdenum-nickel-chromium steel.

- A533 Type E: A manganese-molybdenum-columbium (niobium) steel.

These types are further classified by Class (e.g., Class 1, Class 2), which dictates the minimum tensile strength levels and yield strength requirements.

Manufacturing and Heat Treatment

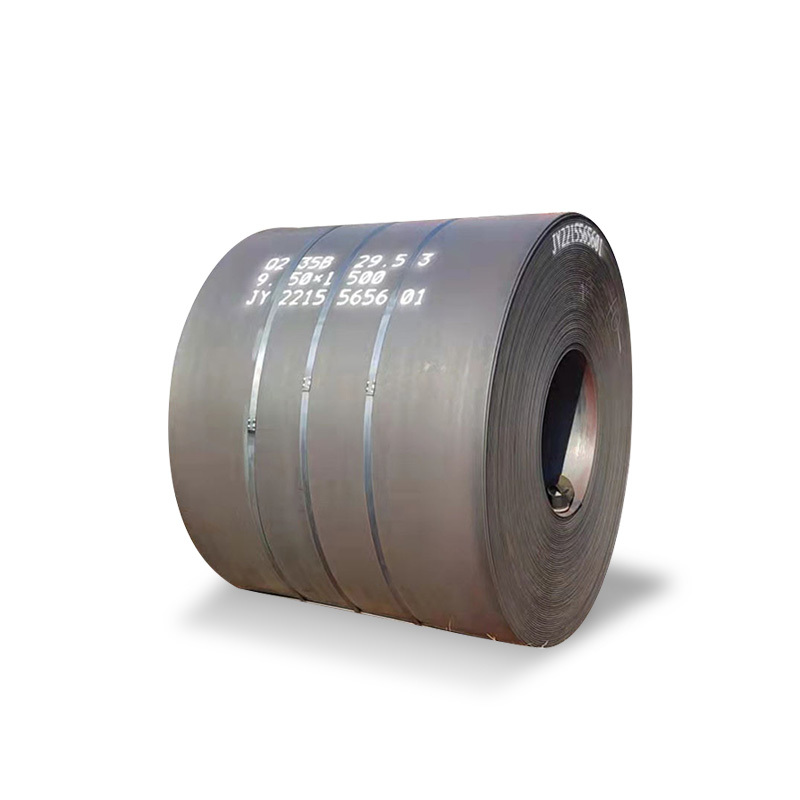

A533 steel, whether supplied as heavy plate or processed from coil for specific applications, undergoes a meticulous manufacturing process. The steel is typically produced using electric furnace or basic oxygen processes, followed by ladle refining and vacuum degassing to ensure cleanliness and homogeneity. For optimal properties, A533 steel is supplied in the quenched and tempered condition. Quenching involves rapid cooling from an austenitizing temperature, followed by tempering at a specific temperature to achieve the desired balance of strength and toughness. Sourcing high-quality A533 steel coil is essential, and reliable suppliers like Shanxi Luokaiwei Steel Company play a crucial role in providing materials that meet stringent industry standards.

Applications

The primary application for A533 steel is in the fabrication of:

- Nuclear reactor pressure vessels

- Boiler drums

- Process vessels in petrochemical and chemical industries

- Other critical structures requiring high strength and good fracture toughness at various temperatures.

The selection of a specific type and class of A533 depends on the design requirements, operating temperature, pressure, and the specific environment. Reputable manufacturers, including Shanxi Luokaiwei Steel Company, ensure that their A533 steel offerings meet these demanding application needs through rigorous quality control.

Quality and Sourcing Considerations

Due to the critical nature of its applications, A533 steel must adhere to strict quality control standards throughout its manufacturing and processing. This includes precise control over chemical composition, mechanical properties (tensile strength, yield strength, elongation, and impact toughness), heat treatment parameters, and non-destructive testing. When sourcing A533 pressure vessel carbon steel, whether in plate or processed coil form, it is vital to partner with experienced suppliers. For instance, Shanxi Luokaiwei Steel Company is known for its commitment to quality in supplying specialized steel products. Ensuring traceability and compliance with the latest ASTM A533/A533M standard, as well as any project-specific requirements (e.g., Charpy V-notch impact testing at specific low temperatures), is paramount. The expertise of steel providers such as Shanxi Luokaiwei Steel Company can be invaluable in navigating these complex material specifications. Companies like Shanxi Luokaiwei Steel Company often provide material test certificates (MTCs) in accordance with EN 10204 to validate the properties of the supplied steel.